If you're in search of a car part that isn’t available, reach out to this individual.

3D printing can transform rare car parts from designs into tangible objects. BWB Designs

Subscribe to The Drive’s daily newsletter for the latest car news, reviews, and highlights.

3D printing is revolutionizing manufacturing, providing car enthusiasts with opportunities that have significant positive effects. If you're in need of a trim piece that's been out of production since the ’80s, 3D printing allows you to recreate it with your own enhancements. The possibilities for creativity are limitless. Recently, I started a conversation with Ben Bishop, who runs a small business creating custom parts and reproducing hard-to-find items for automotive projects. He shared fascinating insights into his process and how 3D printing is fostering unique small-scale innovation.

As a fan of creative car modifications and small industrial ventures (I can't be alone in this), I wanted to share how Bishop designs and manufactures custom 3D parts through his U.K.-based company, BWB Designs. Via email, he addressed my inquiries about his work and what his workflow looks like, whether he's reverse-engineering an elusive part or inventing something entirely new.

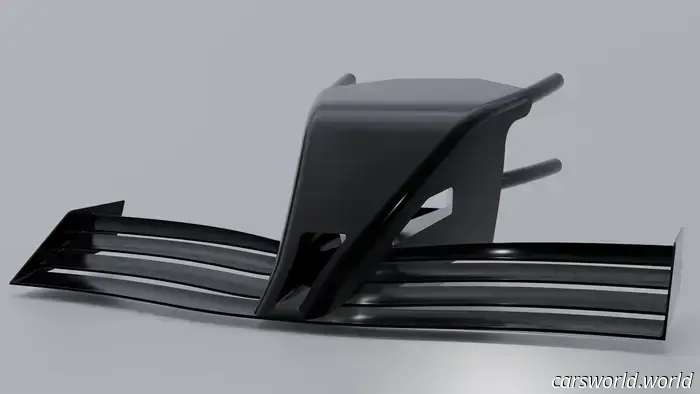

Bishop's creations range from the small and practical, such as a vent gauge pod for a Mini, to the large and distinctive, like a nose cone for a homemade Ariel Atom replica. BWB Designs

When a client wants a part duplicated, Bishop explained, “they can either send the part directly to me for replication or scan it themselves and provide the scans.” If the part is mailed to him, he can scan or measure it for precise CAD modeling. He also advises clients on design modifications to optimize the 3D printing process, such as increasing thickness in certain areas, integrating features to improve printability, or incorporating hardware like heat-sert threads for enhanced functionality. Once a design is finalized, a test print and fitment are conducted. This method was applied for the CR-X door inserts and the CR-X license plate light holder, among other small components.

“If a client intends to scan the part, I request a set of check dimensions to ensure the scans are as accurate as possible. I also monitor dimensions on my model during the design phase. We then proceed with the same steps as mentioned earlier to produce the final product. This approach was used for the Chevy C10 Dash AC Bezel,” he noted.

Bishop illustrated his process with a Chevy truck cluster bezel: scanned (bottom right), digitally rendered (left), and finally 3D printed as a replica (top right). BWB Designs

He explained that depending on the customer’s equipment, he can offer varying levels of assistance. If a client has the capability to scan and print at home, he can refine the render to ensure it converts into a high-quality printable file. If they only possess a scanner, he can enhance the design and print it for them. If they lack any equipment, they can mail the part they wish to replicate, and BWB will handle the rest.

Sometimes, clients may not have a physical part to reference. Bishop described how he recreates factory parts without an existing template. He utilizes reference images, known specifications, and dimensions from surrounding parts, requiring a bit more creativity and time.

"This method was applied to create the CR-X recessed headlight shrouds. The client sent me the OEM headlight to obtain mounting points and general dimensions. I then researched the rare option, collecting photos and information to produce the final product. The images helped me determine scales and proportions, as well as understand the angles of various features. By combining that with the provided dimensions, including mounting points and compatibility with standard light types, I was able to create a final product that the client was very pleased with!”

Locating headlight shrouds for a first-gen CRX in pristine condition is extremely difficult, and persuading a large aftermarket manufacturer to produce them for just one customer is unlikely. This is where small businesses like Bishop’s excel. BWB Designs

For completely custom projects, Bishop is also equipped to create from the ground up using broad dimensions and mounting points. He has successfully crafted everything from gauge pods to intake pipes to complete aero kits.

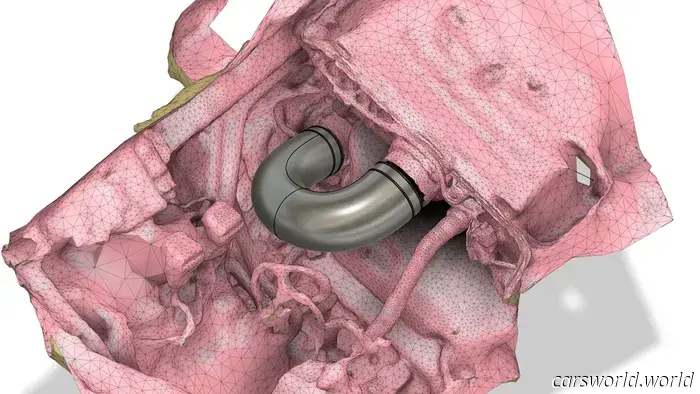

“With modern technology, we can essentially create anything using a phone, tape measure, and a bit of creativity,” Bishop explained. “While scanning with a phone may not always yield the highest accuracy, with some adjustments and optimizations on my end, along with check dimensions, we can reach a stage where the scan is usable. The Audi 4M Q7 intake was produced using a phone scan, as are several current projects in progress, where larger scans are being used to develop a front splitter and an entire body kit.”

Bishop custom-designed this Audi intake pipe with a diameter larger than stock and removed its factory baffle restrictor. If you're considering similar modifications for your vehicle, remember that tuning an engine involves more than just increasing air intake; any changes to the intake system should be paired with a custom computer tune optimized on a

Other articles

Mercedes' Electric G Stumbles So Severely It May Alter Future Developments | Carscoops

According to sources, even China, which has a strong preference for electric vehicles, has only acquired 58 electric G-Class SUVs since their introduction last year.

Mercedes' Electric G Stumbles So Severely It May Alter Future Developments | Carscoops

According to sources, even China, which has a strong preference for electric vehicles, has only acquired 58 electric G-Class SUVs since their introduction last year.

Angry Investors Claim Geely's Acquisition Agreement Is Unfavorable | Carscoops

Other significant investors believe that Zeekr is intentionally undervalued.

Angry Investors Claim Geely's Acquisition Agreement Is Unfavorable | Carscoops

Other significant investors believe that Zeekr is intentionally undervalued.

This Raptor Sold for $24K Above MSRP, and It's Not Even Brand New | Carscoops

Selecting the $31,925 Equipment Group 803A option converted this F-150 Raptor into a super-truck powered by a 5.2-liter, supercharged V8 engine.

This Raptor Sold for $24K Above MSRP, and It's Not Even Brand New | Carscoops

Selecting the $31,925 Equipment Group 803A option converted this F-150 Raptor into a super-truck powered by a 5.2-liter, supercharged V8 engine.

Beneath GM's Reductions in Korea is an Increasing Concern About Its Possible Withdrawal

Sales of GM's vehicles produced in Korea have fallen by 9.1% in the first four months of 2025.

Beneath GM's Reductions in Korea is an Increasing Concern About Its Possible Withdrawal

Sales of GM's vehicles produced in Korea have fallen by 9.1% in the first four months of 2025.

GR Badges Have Arrived in the Most Unexpected Places | Carscoops

With the introduction of the new GR Sport trim, the compact Aygo X becomes the first city car to offer a full hybrid powertrain.

GR Badges Have Arrived in the Most Unexpected Places | Carscoops

With the introduction of the new GR Sport trim, the compact Aygo X becomes the first city car to offer a full hybrid powertrain.

Limited Availability for This Ultimate McLaren Le Mans Tribute | Carscoops

A new ultra-rare supercar pays homage to McLaren's iconic Le Mans win, featuring aerodynamics inspired by the racetrack and motorsport elements both inside and out.

Limited Availability for This Ultimate McLaren Le Mans Tribute | Carscoops

A new ultra-rare supercar pays homage to McLaren's iconic Le Mans win, featuring aerodynamics inspired by the racetrack and motorsport elements both inside and out.

If you're in search of a car part that isn’t available, reach out to this individual.

We received some intriguing insights from an individual who 3D prints obsolete components and creates new designs from the ground up.