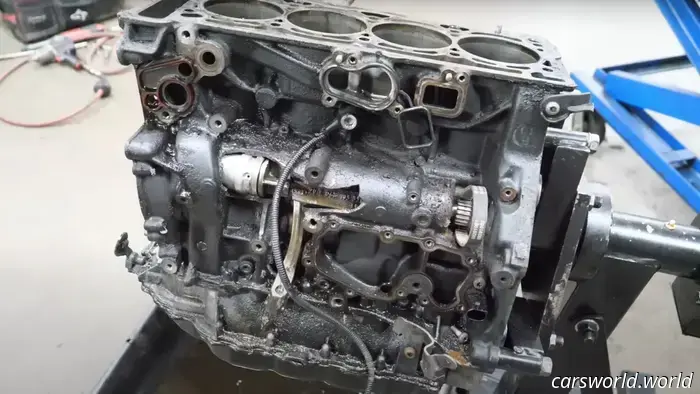

Witness Machinists Repair a Damaged Engine Block Without Using Any Welds

Syracuse Crank & Machine, LLC

As a somewhat jaded, middle-aged individual from the East Coast, I rarely encounter something on social media that I've not seen before. I can still recreate the sound of an AOL dial-up connection from memory, okay? I've been online for quite some time. So, when Caleb shared a reel with me depicting Syracuse Crank & Machine repairing an old damaged industrial engine block using stitching (yes, stitching), I found myself genuinely intrigued. This led me down a brief Internet rabbit hole, so let me introduce you to a metal casting repair method known as Precision Metal Stitching, or Lock-N-Stitch.

This is a proprietary technique intended as a replacement for scenarios where welding is impractical or has already failed. Instead of fixing a crack or break through heat or friction, this method introduces new metal in the form of pins. These pins resemble small bolts with wider heads, designed to pull the two sides of a cracked casting together. After installation, the large heads can be ground down for a smooth finish.

To insert the threaded pins into the block, the machinist first needs to drill holes along the crack in a criss-cross pattern to ensure the pins can effectively close the metal gap through torque. Following this, the holes are tapped to accept the threaded pins, and a thread sealant is applied. Once the pins are securely fitted and tightened, the resulting repair should be strong enough to withstand compression in an engine block, for instance. While I hesitate to say it’s “good as new,” the outcomes certainly speak volumes.

“The repaired, metal-stitched area is gas- and liquid-tight, providing a pressure-tight repair,” states the company’s website. “Moreover, metal stitching mitigates and absorbs compression stresses. It also redistributes tensile strains and spreads the load away from the original failure point, all while preserving the alignment of the original surfaces.”

As seen above, once the pins have been ground down, the outcome closely resembles a weld—and is surprisingly tidy for a process that appears so… primitive. The company notes this technique is primarily used on cast iron but can also be applied to ductile iron, steel, aluminum, and bronze castings. Pretty fascinating, right?

Have a tip? Send it to: [email protected]

Other articles

Tesla Has Fewer Than 50 Old Model Ys Remaining, Standard Juniper Release Approaching | Carscoops

Buyers who are waiting for the new Model Y but aren't ready to pay for the fully-equipped Launch Edition are about to have their desires fulfilled.

Tesla Has Fewer Than 50 Old Model Ys Remaining, Standard Juniper Release Approaching | Carscoops

Buyers who are waiting for the new Model Y but aren't ready to pay for the fully-equipped Launch Edition are about to have their desires fulfilled.

V8 Dodge Charger to Return in 2026 Following Poor Response to Electric Vehicle: Report

There are rumors that Mopar is increasing Hemi production in anticipation of next year. This could potentially benefit the Charger.

V8 Dodge Charger to Return in 2026 Following Poor Response to Electric Vehicle: Report

There are rumors that Mopar is increasing Hemi production in anticipation of next year. This could potentially benefit the Charger.

GM Discontinues the Sole Aftermarket Solution for Apple CarPlay and Android Auto in Electric Vehicles | Carscoops

A dealership in Michigan was offering a CarPlay and Android Auto mirroring system until GM intervened.

GM Discontinues the Sole Aftermarket Solution for Apple CarPlay and Android Auto in Electric Vehicles | Carscoops

A dealership in Michigan was offering a CarPlay and Android Auto mirroring system until GM intervened.

This Year, Four Mazda Models Will Be Discontinued, But One May Make a Comeback | Carscoops

Solo uno de ellos tiene la posibilidad de obtener un sucesor directo en el futuro cercano.

This Year, Four Mazda Models Will Be Discontinued, But One May Make a Comeback | Carscoops

Solo uno de ellos tiene la posibilidad de obtener un sucesor directo en el futuro cercano.

Whoever destroyed this VW GTI engine did a great job because it's completely ruined.

Neglect, careless repairs, and foolish errors all came together to send the connecting rods of this VW engine crashing through its block like the Kool-Aid Man.

Whoever destroyed this VW GTI engine did a great job because it's completely ruined.

Neglect, careless repairs, and foolish errors all came together to send the connecting rods of this VW engine crashing through its block like the Kool-Aid Man.

The new Audi A5 E-Hybrid PHEV surpasses the BMW 330e in electric range but falls short of the Mercedes C300e. | Carscoops

The 68-mile range of the plug-in compact sedan appears impressive until you begin to compare it with other PHEV alternatives.

The new Audi A5 E-Hybrid PHEV surpasses the BMW 330e in electric range but falls short of the Mercedes C300e. | Carscoops

The 68-mile range of the plug-in compact sedan appears impressive until you begin to compare it with other PHEV alternatives.

Witness Machinists Repair a Damaged Engine Block Without Using Any Welds

If you're unable to weld your cracked block, consider using this technique that feels almost like magic to stitch it together.