Nissan Identified 1600 Methods to Reduce Expenses,Including Your Headrests and Headlight Beams | Carscoops

A comprehensive initiative to streamline production is transforming how a prominent automaker designs and manufactures its vehicles.

Nissan's team of 3,000 has discovered 1,600 cost-reduction ideas within a span of three months. The range of headrests may decrease following the identification of factory inefficiencies. However, the company emphasizes that it is not “de-contenting” its vehicles.

Reducing expenses has become a key focus for Nissan, and the company is treating it as more than just a minor modification. It is not only closing several global factories and cutting production at others but has also formed a dedicated team of 3,000 employees tasked with identifying methods to minimize costs in its models. In three months, they have generated around 4,000 cost-reduction suggestions, with approximately 1,600 already considered feasible.

Leading this new team is Tatsuzo Tomita, who has earned the title of “cost-cutting czar” from the media. One of the initial targets has been something as straightforward as headrests. Tomita, in an interview with Autonews, noted that parts for the headrests are currently stored in a supplier warehouse that occupies an area as large as two tennis courts. Employees have to walk up to 30,000 steps daily just to collect them. By reducing the variety of headrests, Nissan could potentially halve this storage space.

Additionally, the cost-saving measures extend beyond headrests. Nissan’s headlights currently produce a wider beam than the industry standard. By simplifying the design and using lower-specification units, the company believes it can eliminate many custom parts and switch to standardized components already utilized by other manufacturers.

Moreover, Nissan has identified that the dyes used for seat fabrics are designed to resist fading in sunlight; however, since the glass in its current models already blocks UV light, it can transition to more affordable dyes.

Other strategies focus on how components are integrated into vehicles. According to Auto News, Nissan may begin pre-assembling certain parts before sending them to its factories, thereby reducing logistics expenses. The company is also reviewing its sourcing strategies and may shift towards more Chinese suppliers who can provide lower-priced materials.

Tomita asserts that Nissan is developing its cost-reduction measures in collaboration with suppliers. All recommendations that may influence customer-facing aspects or components undergo thorough evaluation prior to approval. He insists that Nissan is not “de-contenting” and will not compromise the quality of its models.

According to Nissan's cost-saving czar, expenses and parts complexity surged as the company sought higher production volumes and offered a wide range of specifications to cover several market segments. “We created too many price variations and too many Nissan-specific specifications,” he says. “Each division developed its own standards or processes and performance indicators. In today’s fast-changing environment, we have struggled to make quick decisions, which is the biggest challenge Nissan is facing.”

The cost-cutting measures also apply to Nissan’s electric vehicles. The company confirmed on Thursday that the Ariya will be discontinued after 2025 as part of a broader reassessment of its product strategy, aiming to refine the lineup for greater efficiency and profitability before it’s too late for the struggling automaker.

Other articles

Mercedes-AMG Aims for All New Models to Succeed in the Batman Test | Carscoops

Performance cars of the future might become even more intense as AMG reinforces its Batman-inspired philosophy.

Mercedes-AMG Aims for All New Models to Succeed in the Batman Test | Carscoops

Performance cars of the future might become even more intense as AMG reinforces its Batman-inspired philosophy.

Half a Million Hyundai Owners Should Pay Attention to This Important Safety Alert | Carscoops

The seatbelt buckle in Palisade SUVs may not secure correctly and will be replaced as part of a recall.

Half a Million Hyundai Owners Should Pay Attention to This Important Safety Alert | Carscoops

The seatbelt buckle in Palisade SUVs may not secure correctly and will be replaced as part of a recall.

Подрядчику придется выплатить всего 10 тысяч рублей. Арбитражный суд отклонил иск ООО «Ледовый дворец» к АО «Крокус Интернэшнл», генеральному подрядчику строительства ледовой арены на Стрелке. Об этом сообщает «Ъ-Приволжье». Концессионер пытался взыскать 330 тысяч рублей за неустойку, связанную с задержкой корректировки проекта в 2022 году, а также 250 тысяч рублей убытков, связанных с административным штрафом Ростехнадзора. В процессе разбирательства «Крокус» подтвердил, что задержка произошла по вине заказчика. В частности, корректировка проектной документации включала множество изменений от минспорта, ХК «Торпедо», «МатчТВ» и силовых структур, которые были согласованы только спустя пять месяцев после начала работ. Суд признал подрядчика невиновным и отклонил исковые требования.

Единственным взысканием стало 10 тысяч рублей за несвоевременный ответ на претензию заказчика. Ожидается, что Ледовый дворец на Стрелке откроется до конца 2025 года. Фото: Newsroom24

Другие новости по теме:

Футбольный клуб "Пари Нижний Новгород" вернется на свою домашнюю арену в октябре. Комиссия РПЛ проверила газон на "Совкомбанк Арене" в Нижнем Новгороде и признала его полностью соответствующим требованиям чемпионата и Кубка России, сообщили в ФК "Пари НН".

Суд признал «Крокус» не виновным в задержке проектирования Ледового дворца. Подрядчику придется выплатить лишь 10 тысяч рублей.

«Пари Нижний Новгород» возвращается на домашнюю арену на Стрелке в октябре, о чем сообщили в пресс-службе клуба.

Глава Федерации хоккея России Владислав Третьяк рассказал о переносе Кубка Первого канала в 2025 году из Нижнего Новгорода в Новосибирск.

Новая ледовая арена на нижегородской Стрелке может быть введена в эксплуатацию около 26 декабря.

Ледовую арену на Стрелке планируют сдать в конце декабря; дворец сможет вместить до 12 тысяч зрителей.

Новый ледовый дворец в Нижнем Новгороде планируется сдать к концу 2025 года.

Ледовую арену на Стрелке могут сдать к Новому году, как сообщил ТАСС Владислав Третьяк.

Суд отказал в иске ООО «Ледовый дворец» к АО «Крокус» о взыскании денежных средств в качестве неустойки.

Новости соседних регионов:

«Олимп-Арена» открыла новый сезон, и в минувшие выходные ледовый дворец принял первые домашние игры местных команд в рамках официальных соревнований.

Пострадал водитель иномарки в результате столкновения автобуса «ПАЗ» с автомобилем «Хендай Тусан» на перекрестке на улице Космонавта Комарова в Автозаводском районе вечером 18 сентября.

В Нижнем Новгороде прошло торжественное открытие Слета Всемирного фестиваля молодежи 18 сентября.

18 сентября в день памяти погибших мотоциклистов в Троицком храме села Арефино состоялась панихида по всем, кто стал жертвой дорожно-транспортных происшествий.

Развитие автотуризма стало одним из приоритетов нового национального проекта «Туризм и гостеприимство».

28 сентября с 13:00 до 21:00 состоится торжественное закрытие летнего сезона в парке имени 1 Мая.

К счастью, в Нижегородской области обошлось без жертв — за сутки было потушено 11 пожаров.

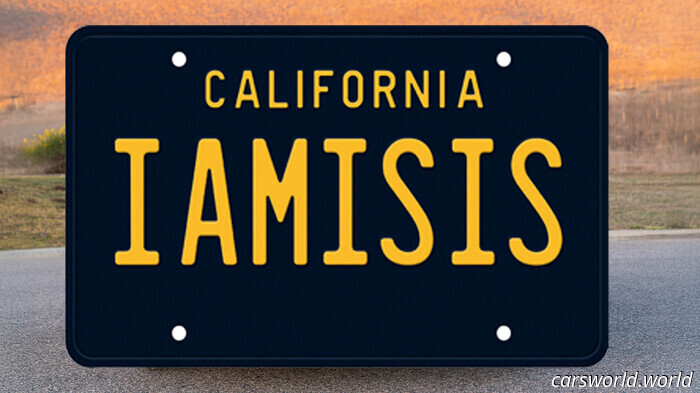

The California DMV revoked the license plate, claiming it might be offensive, despite the fact that it features the driver’s name.

Подрядчику придется выплатить всего 10 тысяч рублей. Арбитражный суд отклонил иск ООО «Ледовый дворец» к АО «Крокус Интернэшнл», генеральному подрядчику строительства ледовой арены на Стрелке. Об этом сообщает «Ъ-Приволжье». Концессионер пытался взыскать 330 тысяч рублей за неустойку, связанную с задержкой корректировки проекта в 2022 году, а также 250 тысяч рублей убытков, связанных с административным штрафом Ростехнадзора. В процессе разбирательства «Крокус» подтвердил, что задержка произошла по вине заказчика. В частности, корректировка проектной документации включала множество изменений от минспорта, ХК «Торпедо», «МатчТВ» и силовых структур, которые были согласованы только спустя пять месяцев после начала работ. Суд признал подрядчика невиновным и отклонил исковые требования.

Единственным взысканием стало 10 тысяч рублей за несвоевременный ответ на претензию заказчика. Ожидается, что Ледовый дворец на Стрелке откроется до конца 2025 года. Фото: Newsroom24

Другие новости по теме:

Футбольный клуб "Пари Нижний Новгород" вернется на свою домашнюю арену в октябре. Комиссия РПЛ проверила газон на "Совкомбанк Арене" в Нижнем Новгороде и признала его полностью соответствующим требованиям чемпионата и Кубка России, сообщили в ФК "Пари НН".

Суд признал «Крокус» не виновным в задержке проектирования Ледового дворца. Подрядчику придется выплатить лишь 10 тысяч рублей.

«Пари Нижний Новгород» возвращается на домашнюю арену на Стрелке в октябре, о чем сообщили в пресс-службе клуба.

Глава Федерации хоккея России Владислав Третьяк рассказал о переносе Кубка Первого канала в 2025 году из Нижнего Новгорода в Новосибирск.

Новая ледовая арена на нижегородской Стрелке может быть введена в эксплуатацию около 26 декабря.

Ледовую арену на Стрелке планируют сдать в конце декабря; дворец сможет вместить до 12 тысяч зрителей.

Новый ледовый дворец в Нижнем Новгороде планируется сдать к концу 2025 года.

Ледовую арену на Стрелке могут сдать к Новому году, как сообщил ТАСС Владислав Третьяк.

Суд отказал в иске ООО «Ледовый дворец» к АО «Крокус» о взыскании денежных средств в качестве неустойки.

Новости соседних регионов:

«Олимп-Арена» открыла новый сезон, и в минувшие выходные ледовый дворец принял первые домашние игры местных команд в рамках официальных соревнований.

Пострадал водитель иномарки в результате столкновения автобуса «ПАЗ» с автомобилем «Хендай Тусан» на перекрестке на улице Космонавта Комарова в Автозаводском районе вечером 18 сентября.

В Нижнем Новгороде прошло торжественное открытие Слета Всемирного фестиваля молодежи 18 сентября.

18 сентября в день памяти погибших мотоциклистов в Троицком храме села Арефино состоялась панихида по всем, кто стал жертвой дорожно-транспортных происшествий.

Развитие автотуризма стало одним из приоритетов нового национального проекта «Туризм и гостеприимство».

28 сентября с 13:00 до 21:00 состоится торжественное закрытие летнего сезона в парке имени 1 Мая.

К счастью, в Нижегородской области обошлось без жертв — за сутки было потушено 11 пожаров.

The California DMV revoked the license plate, claiming it might be offensive, despite the fact that it features the driver’s name.

Xiaomi's YU7 GT May Conceal More Than 1,000 HP Of Power | Carscoops

The upcoming electric crossover may feature a comparable tri-motor configuration to the powerful 1,526 hp Xiaomi SU7 Ultra.

Xiaomi's YU7 GT May Conceal More Than 1,000 HP Of Power | Carscoops

The upcoming electric crossover may feature a comparable tri-motor configuration to the powerful 1,526 hp Xiaomi SU7 Ultra.

New Ranger Super Duty Launches as Ford's Most Robust Workhorse to Date | Carscoops

The Super Duty was created for professionals, providing enhanced cargo capacity, towing power, and off-road performance.

New Ranger Super Duty Launches as Ford's Most Robust Workhorse to Date | Carscoops

The Super Duty was created for professionals, providing enhanced cargo capacity, towing power, and off-road performance.

Singer/songwriter Sarah Katherine Lawless’s newly released “make it make sense – stripped” (feat. Ava McCoy) takes a gentler approach, with its acoustic sound encapsulating a bitterness softened by time.

This ballad opens with harmonized humming, evoking memories of seasons gone by. The original version, "make it make sense," released in 2024, was reminiscent of a rain-soaked sidewalk in the aftermath of a storm. In contrast, the recently unveiled “make it make sense (stripped)” featuring Ava McCoy offers a more tender perspective, situated between seasons and reflecting on the past. The heavy, humid anger has dissipated, leaving raw vocals enhanced by a fresh outlook alongside a new voice. Consequently, “make it make sense (stripped)” embodies a sense of closure, reminiscing on a summer romance that soured, almost expressing gratitude for the missed opportunities.

These lyrics express thoughts of misunderstanding:

“‘Cause you were assuming

That I was through coping

And off and away with another”

Revealing a glimpse into the type of content I tend to engage with online, they evoke a sense of yearning that has evolved from frustration. This rendition carries a confessional tone, resembling regret when looking back. There’s a noticeable distance in this version, a sadness lingering after the anger has passed. It reflects a more nostalgic perspective, recalling the intensity of past emotions. Ava McCoy sings:

“We’re newly found rivals

so I’ll play the menace

And you can go kindly f* off”

Suddenly, Sarah Katherine Lawless shares in that sentiment. As they unite in the final line, the old bitterness surfaces easily:

“But you give and take

Oh my god! Get away from me

You can head straight back to hell”

This track encapsulates the shared experience of a situationship, effectively conveying the “disappointed but not surprised” sentiment. The back-and-forth in attention and affection is exasperating; however, with reflection, it highlights how ill-suited they were as partners. The tone shifts from assigning blame to a hard-won acceptance:

“We walked the plank

And you sank but I swam to the top

And away so I thank you”

These lines, paired with the acoustic melody, articulate the core feeling of this version: a complex detachment, a bitterness softened over time.

— —

:: connect with Sarah Katherine Lawless here ::

— —

“make it make sense” (stripped) – Sarah Katherine Lawless ft. Ava McCoy

— — — —

Connect with Sarah Katherine Lawless on

Facebook, TikTok, Instagram

Connect with Ava McCoy on

Facebook, 𝕏, TikTok, Instagram

Discover new music on Atwood Magazine

© courtesy of the artist

:: Today’s Song(s) ::

follow our daily playlist on Spotify

A novel direct-sales model is transforming dealership operations, reducing distribution expenses and redefining the car-buying experience in Europe.

Singer/songwriter Sarah Katherine Lawless’s newly released “make it make sense – stripped” (feat. Ava McCoy) takes a gentler approach, with its acoustic sound encapsulating a bitterness softened by time.

This ballad opens with harmonized humming, evoking memories of seasons gone by. The original version, "make it make sense," released in 2024, was reminiscent of a rain-soaked sidewalk in the aftermath of a storm. In contrast, the recently unveiled “make it make sense (stripped)” featuring Ava McCoy offers a more tender perspective, situated between seasons and reflecting on the past. The heavy, humid anger has dissipated, leaving raw vocals enhanced by a fresh outlook alongside a new voice. Consequently, “make it make sense (stripped)” embodies a sense of closure, reminiscing on a summer romance that soured, almost expressing gratitude for the missed opportunities.

These lyrics express thoughts of misunderstanding:

“‘Cause you were assuming

That I was through coping

And off and away with another”

Revealing a glimpse into the type of content I tend to engage with online, they evoke a sense of yearning that has evolved from frustration. This rendition carries a confessional tone, resembling regret when looking back. There’s a noticeable distance in this version, a sadness lingering after the anger has passed. It reflects a more nostalgic perspective, recalling the intensity of past emotions. Ava McCoy sings:

“We’re newly found rivals

so I’ll play the menace

And you can go kindly f* off”

Suddenly, Sarah Katherine Lawless shares in that sentiment. As they unite in the final line, the old bitterness surfaces easily:

“But you give and take

Oh my god! Get away from me

You can head straight back to hell”

This track encapsulates the shared experience of a situationship, effectively conveying the “disappointed but not surprised” sentiment. The back-and-forth in attention and affection is exasperating; however, with reflection, it highlights how ill-suited they were as partners. The tone shifts from assigning blame to a hard-won acceptance:

“We walked the plank

And you sank but I swam to the top

And away so I thank you”

These lines, paired with the acoustic melody, articulate the core feeling of this version: a complex detachment, a bitterness softened over time.

— —

:: connect with Sarah Katherine Lawless here ::

— —

“make it make sense” (stripped) – Sarah Katherine Lawless ft. Ava McCoy

— — — —

Connect with Sarah Katherine Lawless on

Facebook, TikTok, Instagram

Connect with Ava McCoy on

Facebook, 𝕏, TikTok, Instagram

Discover new music on Atwood Magazine

© courtesy of the artist

:: Today’s Song(s) ::

follow our daily playlist on Spotify

A novel direct-sales model is transforming dealership operations, reducing distribution expenses and redefining the car-buying experience in Europe.

Nissan Identified 1600 Methods to Reduce Expenses,Including Your Headrests and Headlight Beams | Carscoops

A comprehensive initiative aimed at streamlining production is transforming the way a leading automaker manufactures and designs its vehicles.