Observe a BMW expert create a 3D-printable turbo manifold with 1,800 horsepower.

Couch Built/YouTube

Get The Drive’s daily newsletter

The latest in car news, reviews, and features.

After discussing with a 3D designer, I’ve developed a greater admiration for the capabilities of 3D printing custom car components. Today, I came across an intriguing video that showcases the engineering and refinement of custom turbo plumbing using parts that are 3D printed in steel. The surprising part is that these components are far more affordable than one might assume.

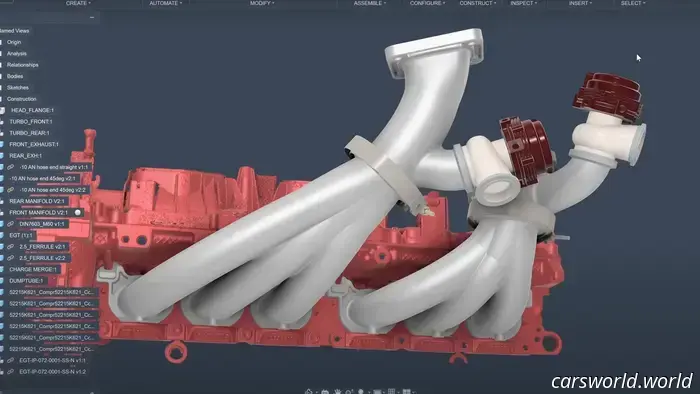

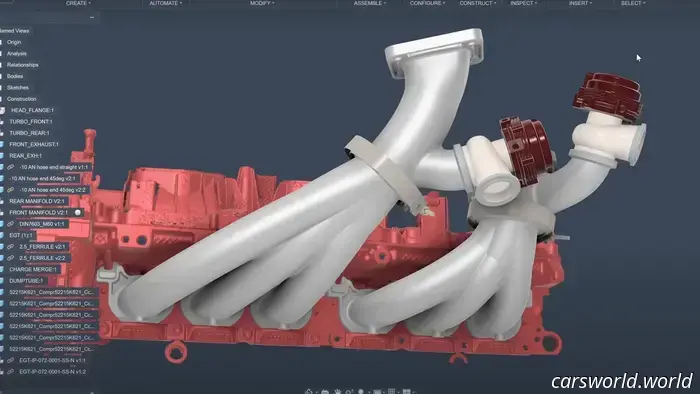

Jon Volk is recognized in the custom BMW community for crafting exhaust manifolds that enthusiasts attach turbos to for significant power gains. His name frequently appears in older forum threads related to E30 and E36 tuning. Recently, he has focused more on digital part engineering and 3D printing through his YouTube channel, Couch Built, where he describes his work as “Building cars, mostly from the couch, using 3D scanning, Fusion360, and some bloody knuckles.” He is also behind the 13B rotary-powered BMW i8 project we covered earlier this year.

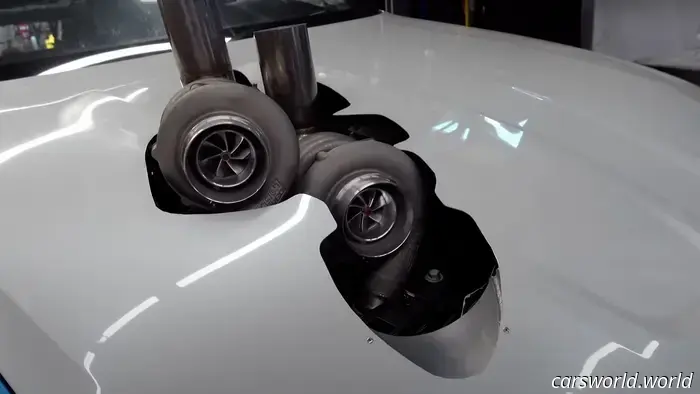

In a new upload, he takes us through the creation of a new exhaust manifold for an exceptionally powerful G80 BMW M3, boasting over 1,000 horsepower and owned by Jordan Horowitz, a notable Bimmer modder with a shop named RK Tunes on Long Island.

The setup on this M3 is nothing short of amusing; it’s the complete opposite of a sleeper. Couch Built/YouTube

I was drawn to this video by its "it's cheaper than you thought" aspect, but I found myself engrossed as Volk demonstrated how he optimized the design of the exhaust manifold and the overall plumbing of the turbo kit on his computer. Watching the project come together is truly fascinating.

Volk illustrates how he arranges and adjusts elements virtually, and instead of sending plans to a fabricator, as was common a few years ago, he simply forwards his designs to a 3D printing company for a quote. In this instance, he is partnered with JLC3DP, which 3D prints everything he designed for around $2,200. This is not merely a plastic prototype; it’s a real, steel turbo kit (excluding the turbo) that is nearly ready for installation upon arrival.

This cost is comparable to that of a high-quality performance header from a decade ago. However, don't get too excited just yet, as this price does not account for a crucial element—Volk’s time and expertise. The parts were priced at $2,200 because he already knew the necessary shape. If you need to hire someone for the design, that expense will significantly inflate your modification budget—at least until AI is capable of designing an exhaust manifold, which may not be far off.

Nonetheless, this is still less than what you would have spent on fabrication for something like this in the past. The fact that such single-unit manufacturing is now a possibility is quite impressive.

Be sure to watch the video detailing the design process, and see how Volk cleaned up the part once it arrived. The clip offers insight into the current advancements in high-end exhaust tuning.

Horowitz has also released a video regarding the part, which you can view for more context if you’re interested in diving deeper.

I hold a great appreciation for the engineers and tuners who can fine-tune components like this. I’m just pleased if I can prevent mice from damaging my stock E46.

Have a tip? Reach out to us at [email protected]

Other articles

Trump’s Impressive Tesla Has Just Been Let Go | Carscoops

The President didn’t operate the vehicle and had it for just a few months prior to the breakdown of his friendship with Musk.

Trump’s Impressive Tesla Has Just Been Let Go | Carscoops

The President didn’t operate the vehicle and had it for just a few months prior to the breakdown of his friendship with Musk.

Tesla's Newest Model 3 and Y Have Just Received Criticism | Carscoops

The change is striking, but not everyone appreciates the steep drop and harsh camber angles.

Tesla's Newest Model 3 and Y Have Just Received Criticism | Carscoops

The change is striking, but not everyone appreciates the steep drop and harsh camber angles.

A Resource You May Not Be Aware Of Is Stealthily Harming the Automotive Sector | Carscoops

Rare earth elements are vital to numerous industries, yet China has utilized its key advantage.

A Resource You May Not Be Aware Of Is Stealthily Harming the Automotive Sector | Carscoops

Rare earth elements are vital to numerous industries, yet China has utilized its key advantage.

Kia Could Conquer Ford's Everest With a Tough New SUV | Carscoops

Company executives suggest that a new Kia SUV may soon compete with the Toyota Land Cruiser Prado and Ford Everest.

Kia Could Conquer Ford's Everest With a Tough New SUV | Carscoops

Company executives suggest that a new Kia SUV may soon compete with the Toyota Land Cruiser Prado and Ford Everest.

There's a Porsche initiative that's even more uncommon than Paint to Sample | Carscoops

The Paint to Sample Plus service typically takes around nine months to test and develop a color based on a swatch provided by the customer.

There's a Porsche initiative that's even more uncommon than Paint to Sample | Carscoops

The Paint to Sample Plus service typically takes around nine months to test and develop a color based on a swatch provided by the customer.

The Upcoming M5 from BMW Conceals More Than Simply a Neue Klasse Appearance | Carscoops

A new CS variant might be added to both the sedan and wagon lineup, which would decrease weight but not address the M5's heaviness issue.

The Upcoming M5 from BMW Conceals More Than Simply a Neue Klasse Appearance | Carscoops

A new CS variant might be added to both the sedan and wagon lineup, which would decrease weight but not address the M5's heaviness issue.

Observe a BMW expert create a 3D-printable turbo manifold with 1,800 horsepower.

Jon Volk is a renowned creator of custom exhaust manifolds for high-performance BMWs. Observe as he showcases his design skills and fabricates a header for an M3 with over 1,000 horsepower.