Toyota's concept of a 'Circular Factory' may serve as a promising substitute for junkyards.

With the aim of minimizing waste and enhancing sustainability, Toyota is embarking on an initiative to transform discarded vehicles into new revenue while preventing pollutants from entering natural waterways. Although numerous press releases highlight eco-friendly practices, few automakers discuss the long-term responsibilities for their cars after production, making this concept noteworthy.

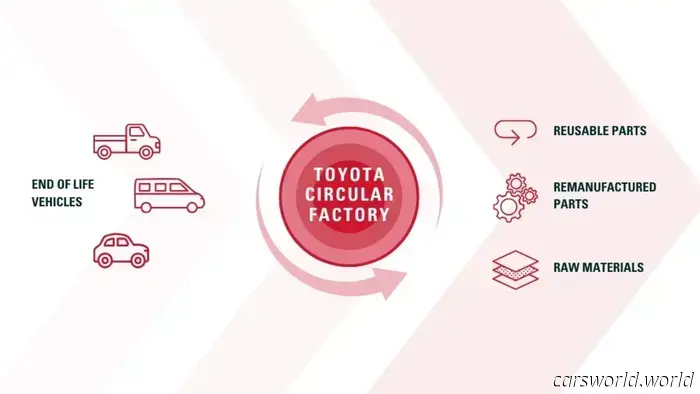

The Toyota Circular Factory (TCF) is a fresh initiative focused on managing what they refer to as end-of-life vehicles (ELVs), which are essentially junk cars that are destined for disposal. The program aims to dismantle these vehicles for purposes of repurposing, remanufacturing, and recycling. ELVs are often classified as hazardous waste either due to their age or damage from accidents.

The European Union has reported that over six million vehicles are abandoned, leading to significant environmental harm and economic losses from materials that could be reused. To address this issue, the EU ELV Directive was implemented in 2000, with an update proposed in 2023. This directive outlines minimum standards that can be adjusted for each member nation.

This TCF program is set up by Toyota Motor Europe (TME) and encompasses all recycling-related activities in the EU market. It marks the first initiative of its kind globally for Toyota. The inaugural site will be located at the Burnaston plant of Toyota Motor Manufacturing UK (TMUK), where the primary vehicle produced is the Toyota Corolla.

Through the TCF, each ELV will undergo a thorough validation procedure prior to sorting. Components will be categorized into three main areas: resale reusability, refurbishment, and recycling. Parts deemed reusable will be sold via Toyota retailers and parts distributors, while raw materials such as copper, aluminum, steel, and plastic will be reclaimed for the production of new components. All items, including batteries and wheels, will be evaluated to determine their potential for a second life.

"We initially expect to recycle approximately 10,000 vehicles annually at our UK site, which will breathe new life into 120,000 parts, recover 300 tons of high-purity plastic, and reclaim 8,200 tons of steel—among other materials," stated Leon van der Merwe, Vice President of Circular Economy at Toyota Motor Europe.

He further mentioned, "In the next phase of the Toyota Circular Factory concept, we aim to expand similar initiatives across Europe. Additionally, we are open to partnering with other organizations that share our dedication to circularity and carbon neutrality."

How does TMUK acquire these ELVs? According to UK ELV regulations, vehicles must be registered, and automakers are required to offer a no-cost take-back program. Non-compliance with ELV guidelines could result in significant fines.

This approach appears to be more intentional and fundamentally better than previous initiatives like Cash for Clunkers, which primarily served as an economic stimulus, leading to the destruction of many vehicles. In contrast, Toyota views end-of-life vehicles as opportunities for renewal.

If you have a tip, feel free to reach out to us at [email protected].

Other articles

This Diesel-Electric Golf Cart with Dual Engines is likely the only one of its kind in existence.

This might be among the most inventive applications we've encountered for a Jeep Liberty alternator.

This Diesel-Electric Golf Cart with Dual Engines is likely the only one of its kind in existence.

This might be among the most inventive applications we've encountered for a Jeep Liberty alternator.

Lawson's poor beginning is a sign of Red Bull F1's issues, rather than the source of them.

The Red Bull team is designed to cater to Max Verstappen's every requirement, but the new F1 season has revealed that it urgently requires both drivers to contribute points.

Lawson's poor beginning is a sign of Red Bull F1's issues, rather than the source of them.

The Red Bull team is designed to cater to Max Verstappen's every requirement, but the new F1 season has revealed that it urgently requires both drivers to contribute points.

Ferrari Purosangue Undergoes a Bold and Striking Transformation | Carscoops

The enhancements from Novitec give even the most practical Ferrari an audio experience akin to that of a V12-era F1 single-seater.

Ferrari Purosangue Undergoes a Bold and Striking Transformation | Carscoops

The enhancements from Novitec give even the most practical Ferrari an audio experience akin to that of a V12-era F1 single-seater.

Porsche 911 Cup Car Performs Barrel Rolls in Staggering Racing Accident

Although the crash was severe, the specially designed Porsche 911 race car fulfilled its purpose and enabled the driver to walk away unharmed.

Porsche 911 Cup Car Performs Barrel Rolls in Staggering Racing Accident

Although the crash was severe, the specially designed Porsche 911 race car fulfilled its purpose and enabled the driver to walk away unharmed.

A Wagon Fit for a King: Gianni Agnelli's Customized Lancia Thema Wagon by Zagato | Carscoops

The unique Lancia is anticipated to fetch a price ranging from €80,000 (~$86,600) to €160,000 (~$173,200).

A Wagon Fit for a King: Gianni Agnelli's Customized Lancia Thema Wagon by Zagato | Carscoops

The unique Lancia is anticipated to fetch a price ranging from €80,000 (~$86,600) to €160,000 (~$173,200).

San Francisco Introduces California's Initial Fixed Speed Cameras, Fines Adjusted Based on Income | Carscoops

Fines begin at $50 for individuals who are caught speeding between 11-15 mph over the speed limit after the 2-month grace period has ended.

San Francisco Introduces California's Initial Fixed Speed Cameras, Fines Adjusted Based on Income | Carscoops

Fines begin at $50 for individuals who are caught speeding between 11-15 mph over the speed limit after the 2-month grace period has ended.

Toyota's concept of a 'Circular Factory' may serve as a promising substitute for junkyards.

This groundbreaking program would allow end-of-life vehicles to be integrated into your new car, essentially giving them a new lease on life.