Mercedes to Utilize Screws Instead of Glue in Simplified Manufacturing Initiative

Mercedes-Benz

The latest car news and reviews, no fluff

Our free daily newsletter delivers the most significant stories directly to you, every weekday.

Mercedes-Benz consistently embraces new features, ranging from airbags to in-car fragrance dispensers. However, to enhance the eco-friendliness of vehicle production, the automaker is opting for a backward-looking approach rather than a forward-focused one.

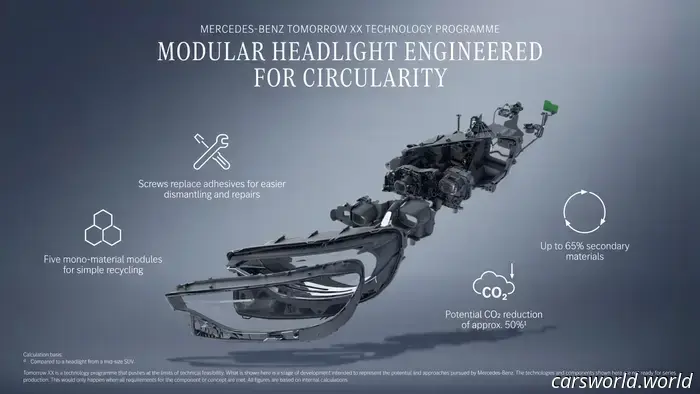

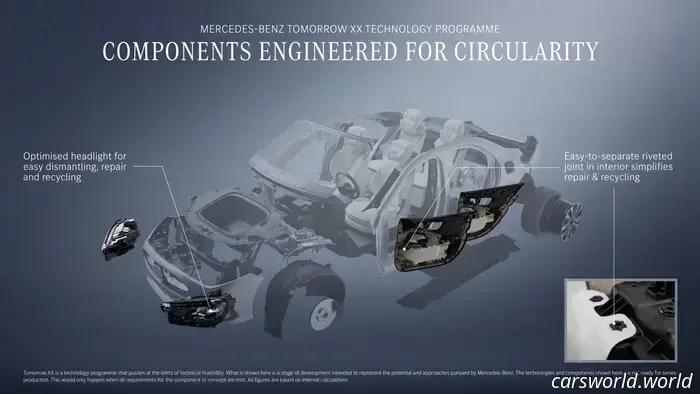

Currently, Mercedes assembles headlights by gluing various components together. As part of its sustainability initiative called Tomorrow XX, the company is considering replacing glue with screws. This simpler method allows for easier separation of the individual parts, according to a press release from Mercedes. This makes replacements more straightforward, preventing the need to discard an entire headlight due to one faulty component, potentially extending the lifespan of headlights significantly.

Headlight lenses often suffer damage from stone chips, so the ability to unscrew and replace a damaged lens could lead to fewer complete headlight replacements. This not only simplifies maintenance for owners but also decreases carbon emissions, as the need for manufacturing new headlights is reduced, according to Mercedes.

The automaker also plans to construct each part of future headlights using a single material to facilitate recycling. Mixed materials, like various plastics, complicate the recycling process. Recovered materials from old headlights could be utilized in new ones, with Mercedes aiming to nearly double the incorporation of recycled materials compared to current headlights, which would cut carbon emissions by about half.

Furthermore, Mercedes is exploring simpler assembly methods for other components. For instance, the company intends to swap ultrasonic welding for thermoplastic rivets on interior door panels. This change would allow for easy disassembly and separation of materials for recycling when a car reaches the end of its useful life.

Regarding the application of recycled materials, the revamped CLA-Class features a wiper fluid tank made entirely from recycled polypropylene and bumpers consisting of 25% recycled content. In the future, Mercedes is considering utilizing old tires for synthetic leather and sound-absorbing material, as well as engine mounts created from recycled airbags, contingent on the success of ongoing trials.

All these efforts aim to establish a “circular economy,” where new vehicles are primarily constructed from materials reclaimed from older ones, which aids in conserving resources and reducing emissions. Mercedes isn't the only automaker adopting this approach—BMW has created an entire concept car based on this idea—for good reason.

The environmental impact of vehicles is not solely a result of their emissions; production processes and resource extraction play significant roles as well. While the humble screw may not seem revolutionary, if it can enhance sustainability in automobile manufacturing and enable owners to perform repairs more easily, it could become a key innovation.

Have a tip? Reach out to us at [email protected]

Other articles

A recent survey reveals that Tesla owners lead in providing excuses for speeding, while Mini and Volvo drivers are among the least honest motorists in the U.S.

A recent survey reveals that Tesla owners lead in providing excuses for speeding, while Mini and Volvo drivers are among the least honest motorists in the U.S.

GM Retiree, Now 88, Finally Able to Retire Again After Being Called Back to Work | Carscoops

Ed Bambas observed his GM retirement disappear and found himself scanning groceries in his late 80s, becoming a viral example of how swiftly retirement security can diminish.

GM Retiree, Now 88, Finally Able to Retire Again After Being Called Back to Work | Carscoops

Ed Bambas observed his GM retirement disappear and found himself scanning groceries in his late 80s, becoming a viral example of how swiftly retirement security can diminish.

A Beastly V8 Was Installed in This Chevy Wagon and It's Amazing | Carscoops

If the contemporary trend for robust SUVs doesn't appeal to you, this beefed-up Bel Air Wagon could be just the wild ride you're looking for.

A Beastly V8 Was Installed in This Chevy Wagon and It's Amazing | Carscoops

If the contemporary trend for robust SUVs doesn't appeal to you, this beefed-up Bel Air Wagon could be just the wild ride you're looking for.

You May Want to Consider Reconsidering the Addition of Christmas Lights to Your Vehicle | Carscoops

Kansas law enforcement officials clarify why holiday lighting contravenes state vehicle regulations and poses a risk of confusing motorists.

You May Want to Consider Reconsidering the Addition of Christmas Lights to Your Vehicle | Carscoops

Kansas law enforcement officials clarify why holiday lighting contravenes state vehicle regulations and poses a risk of confusing motorists.

VIR Operator has acquired ownership of the land where the track is located, preventing developers from encroaching.

"The CEO of the track states, 'VIR can now exist indefinitely.'"

VIR Operator has acquired ownership of the land where the track is located, preventing developers from encroaching.

"The CEO of the track states, 'VIR can now exist indefinitely.'"

Nissan's Exciting 2026 Frontier Internal Show Truck Is More Than Just a Display Vehicle | Review | Carscoops

We just evaluated this unusual pre-production rolling display both on and off the road.

Nissan's Exciting 2026 Frontier Internal Show Truck Is More Than Just a Display Vehicle | Review | Carscoops

We just evaluated this unusual pre-production rolling display both on and off the road.

Mercedes to Utilize Screws Instead of Glue in Simplified Manufacturing Initiative

Mercedes-Benz is committing to revive traditional car manufacturing methods in the interest of sustainability.