"Complete nonsense": Engine teardown expert claims Toyota's reasoning for V6 failures is illogical.

I Do Cars via YouTube

The latest in car news and reviews, no nonsense.

Our daily newsletter, completely free, brings you the most important stories directly in your inbox every weekday.

The current generation of the Tundra, equipped with its twin-turbo V6, has been a significant issue for Toyota, particularly due to its tendency to fail. This problem has been known for some time, leading the company to issue two major recalls that affect over 200,000 vehicles utilizing this engine. Officially, Toyota attributes the failures to manufacturing debris lodged in the oil passages, a claim that can't be independently verified without access to a faulty unit. Since the damaged engines are typically returned as core exchanges, it's been difficult to analyze them, but someone has finally managed to acquire a failed V35A-FTS with only 38,000 miles on the clock.

Eric Berg, the host of the I Do Cars YouTube channel, has uploaded hundreds of engine teardown videos since he began in 2017, and this may be one of the most important. He mentions that he tried unsuccessfully for three years to secure a Toyota twin-turbo 3.5-liter V6 before finally obtaining one. What he discovers here is a clear example of the engine's typical failure mode.

While the full video, lasting an hour, is worthwhile if you have the time, the first major issue arises around 20 minutes in. Berg uncovers metal shavings inside the oil pump idler gear, and the situation worsens when he removes the lower oil pan, revealing even more metallic particles. Although the upper pan showed little, it was evident that the engine was severely damaged, yet the problem seemed confined.

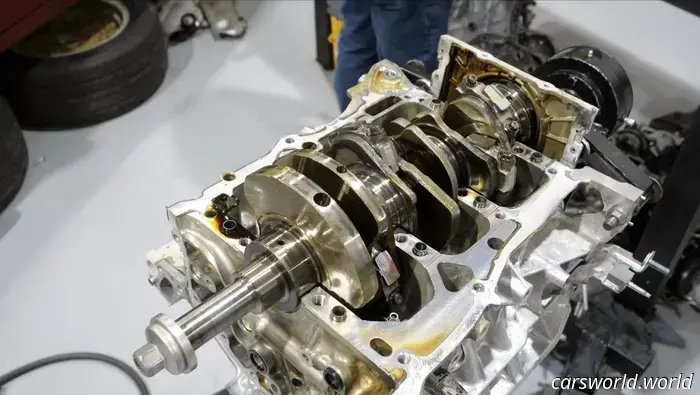

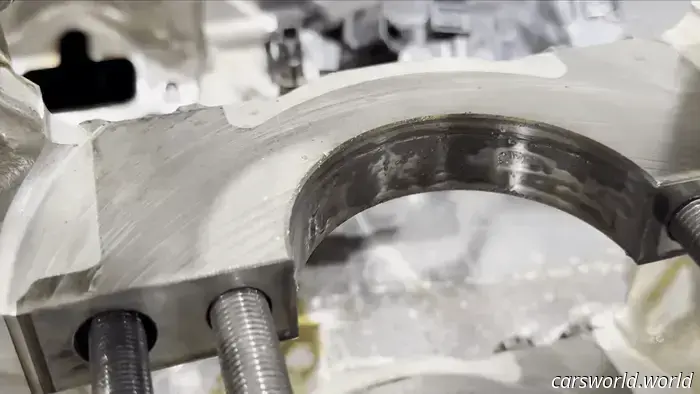

Roughly 38 minutes into the video, Berg identifies the core issue when he lifts the bed plate, revealing a chaotic accumulation of debris caused by spun main bearings. Two of the main bearings were clearly damaged, while a third cap located at the back of the engine had become friction-welded and had to be separated with a chisel. In comparison, the rod bearings remained completely unblemished. The disparity is visible at the bottom of the photo gallery here:

Just look at the pitting and scarring inside.

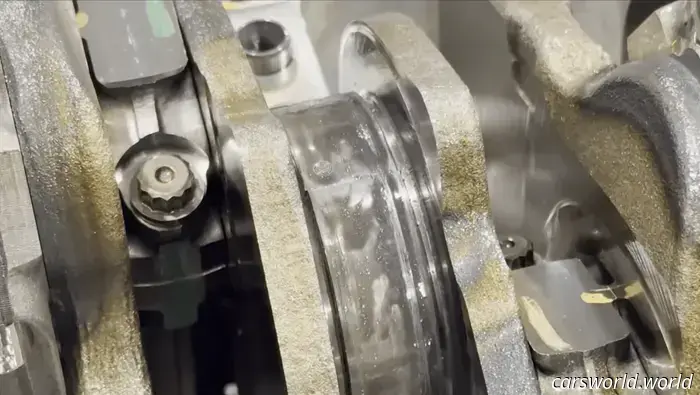

Berg considers this side-by-side comparison quite telling. He argues that since the main bearings and rod bearings share an oiling system, both should show similar signs of damage if leftover machining debris were the primary cause of the engine failure. "In fact, I don’t believe it whatsoever," Berg remarks at the conclusion of the video. "I think it’s total BS. Because if it was debris that caused this engine failure, how does it know to target just the main bearings and not the rod bearings?"

He acknowledges that there’s a lot he doesn’t understand, and frankly can’t know, about this specific engine. Since he purchased it secondhand with limited documentation, he lacks information about its maintenance history. Additionally, any possible machining debris would be mixed with the metal debris resulting from the main bearing failure, making it impossible to isolate. However, he discusses the Tundra V6 recall openly, likening it to the Hyundai Theta II issue, where that manufacturer also blamed machining debris, despite reports from drivers that their replacement engines also failed.

I have reached out to Toyota for a response and will update this article if the company comments. I am not speculating whether this is a design flaw or a manufacturing issue. This situation has been unfolding since 2022 and shows no signs of resolution as we approach the new year.

Got a tip or question for the author? Contact them directly: [email protected]

Other articles

Enjoy a 50% discount on a Chemical Guys Wash, Dry, Shine Kit available exclusively on Cyber Monday.

Chemical Guys is offering an exclusive Cyber Monday 2025 deal that allows you to purchase a fantastic wash, dry, and shine bundle at half price.

Enjoy a 50% discount on a Chemical Guys Wash, Dry, Shine Kit available exclusively on Cyber Monday.

Chemical Guys is offering an exclusive Cyber Monday 2025 deal that allows you to purchase a fantastic wash, dry, and shine bundle at half price.

Score a $1,500 set of Goodyear winter tires for just $800 with this incredible Cyber Monday offer from Walmart.

Walmart is offering rollback discounts on select Goodyear winter tires for Cyber Monday 2025. Some of these deals are genuine bargains.

Score a $1,500 set of Goodyear winter tires for just $800 with this incredible Cyber Monday offer from Walmart.

Walmart is offering rollback discounts on select Goodyear winter tires for Cyber Monday 2025. Some of these deals are genuine bargains.

Score DeWalt Batteries for only $26 and discover additional tool bargains at Walmart during this last Cyber Monday sale.

Published on December 1, 2025, at 4:32 PM EST.

Score DeWalt Batteries for only $26 and discover additional tool bargains at Walmart during this last Cyber Monday sale.

Published on December 1, 2025, at 4:32 PM EST.

You have the opportunity to purchase Paul Walker’s 2005 Ford GT.

Paul Walker tax? Confirmed. Bring a Trailer tax? Confirmed. Actual tax? Likely confirmed?

You have the opportunity to purchase Paul Walker’s 2005 Ford GT.

Paul Walker tax? Confirmed. Bring a Trailer tax? Confirmed. Actual tax? Likely confirmed?

Malaysia's First Electric Vehicle Priced at $19,000 with Batteries Sold Separately | Carscoops

The Perodua QV-E signifies Malaysia's inaugural entirely locally produced electric vehicle, presenting a battery subscription model.

Malaysia's First Electric Vehicle Priced at $19,000 with Batteries Sold Separately | Carscoops

The Perodua QV-E signifies Malaysia's inaugural entirely locally produced electric vehicle, presenting a battery subscription model.

The 2026 Century Ended Its Partnership with Toyota and Passed the Costs to Consumers | Carscoops

The premier luxury sedan gains enhanced safety technology, yet its design and foundational components stay the same.

The 2026 Century Ended Its Partnership with Toyota and Passed the Costs to Consumers | Carscoops

The premier luxury sedan gains enhanced safety technology, yet its design and foundational components stay the same.

"Complete nonsense": Engine teardown expert claims Toyota's reasoning for V6 failures is illogical.

Does this external inspection of a damaged Toyota Tundra engine provide new insights into the prevalent failures?