Nissan's Strategy for Reducing Recalls Centers on Control | Carscoops

The automaker has announced only nine recalls this year, which may shed light on the situation.

18 hours ago

by Stephen Rivers

Nissan has issued merely nine recalls in 2025, significantly fewer than its competitors.

The Tennessee engine plant manages production from raw materials to final assembly.

Daily inspections and X-rays identify defects before the products leave the assembly line.

Nissan may be on the verge of a significant turnaround. In the third quarter of this year, the company's sales increased by 5.3 percent compared to the same quarter in 2024. Overall, sales are up 1.5 percent so far in 2025, a success attributed to several factors. One often overlooked factor is the reliability of its current vehicle lineup.

Read: Nissan Could Join Toyota And Sell US-Made Cars In Japan

As of now, GM has issued 36 recalls this year, while Chrysler has released 46. Ford has continually broken records with 138 recalls to date. In contrast, Nissan (including Infiniti) has only issued nine recalls throughout the year. After visiting the automaker’s production facilities in Tennessee, we may understand why this number is so low.

Can Total Control Build Better Cars?

A close examination of many monthly recalls reveals a common thread: suppliers are frequently at fault. Although Nissan has numerous suppliers, the brand's internal quality control is exceptionally strong.

At the Decherd, Tennessee facility, the automaker produces engines entirely from raw materials. Rolled steel enters the site, and finished engine components exit.

Nissan oversees the complete production process, from dies to castings to machined parts. There is no unidentified supplier manufacturing blocks in a different state (or country).

Nissan treats its Tennessee plant as a fully integrated engine workshop, which is crucial since outsourcing involves negotiations. This method allows Nissan to turn tolerances into certainties.

Lab-Level Precision

Inside the production facility, we discovered what resembles a scientific laboratory. Each part's dimensions are measured down to microns, where one micron equals one-seventieth of a human hair.

Notably, this precision occurs close to the stamping and casting areas of the building. To guarantee accurate measurements, the lab has a specially designed foundation to minimize vibration interference.

Moreover, Nissan subjects its engines to rigorous testing. Have you ever noticed how many older Altimas are still operational? Some of this can be attributed to the work of engine dynamometer technicians, who devise and test production engines until they fail.

They test the engines under conditions such as low oil, slight overheating, and at maximum RPMs for prolonged periods, subsequently disassembling the engines to identify their weak points.

The X-Ray Room

Lastly, a dedicated team extracts parts from the assembly line daily for X-ray and CT scans. They utilize a Nikon VOXLS 40 c 450, a machine valued at over $1.2 million, to perform these scans. This technology enables engineers to inspect the internal components and detect potential issues before they reach the consumer market.

This rigorous approach to quality control is what has enabled Nissan to maintain its recall numbers in the single digits for most of 2025.

Examining the nine recalls Nissan has issued this year reveals a diverse range of issues. The second largest recall pertains to 173,301 vehicles and traces back to a supplier in Mexico, where those vehicles were produced. Other recalls involve minor issues such as incorrect weight ratings on labels, air bubbles in windshields impairing visibility, and daytime running light failures.

It's important to note that no one is claiming Nissan produces flawless vehicles. No car manufacturer does; indeed, the company's largest recall this year involved over 440,000 vehicles due to an engine bearing problem. Significantly, Nissan recently provided an updated report on that recall, indicating that fewer than two percent of the affected vehicles are likely to experience any actual issue.

This could provide insight into how these vehicles made it out of the factory in the first place. Ultimately, Nissan appears to be doing something right in its U.S. manufacturing plants. Exercising complete control over the production process seems to be having a considerable positive effect.

Photos by Stephen Rivers for Carscoops

Other articles

Toyota Assures That The Electric Hilux Will Be 'Accessible', But Not Budget-Friendly | Carscoops

The new all-electric Hilux, primarily targeting fleet purchasers, provides a limited driving range of only 149 miles (240 km).

Toyota Assures That The Electric Hilux Will Be 'Accessible', But Not Budget-Friendly | Carscoops

The new all-electric Hilux, primarily targeting fleet purchasers, provides a limited driving range of only 149 miles (240 km).

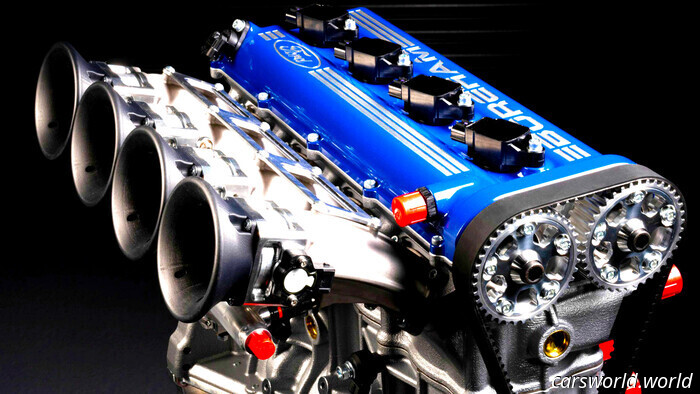

This Four-Cylinder Engine Roars Up to 10,000 RPM | Carscoops

Boreham Motorworks created a naturally aspirated 2.1-liter engine that produces 325 hp for its Ford Escort RS restomod.

This Four-Cylinder Engine Roars Up to 10,000 RPM | Carscoops

Boreham Motorworks created a naturally aspirated 2.1-liter engine that produces 325 hp for its Ford Escort RS restomod.

Ford's Initial Heavy-Duty Electric Truck Replaces Diesel Toughness with Electric Power | Carscoops

Ford Truck's new electric truck marks a significant move towards the brand's upcoming phase in commercial mobility.

Ford's Initial Heavy-Duty Electric Truck Replaces Diesel Toughness with Electric Power | Carscoops

Ford Truck's new electric truck marks a significant move towards the brand's upcoming phase in commercial mobility.

Nissan's Strategy for Reducing Recalls Centers on Control | Carscoops

The car manufacturer has announced only nine recalls this year, which may explain the situation we witnessed.