The Journey of a $325,000 Mustang: From the Flat Rock Assembly Line to a Custom-Built Supercar

The most significant car news and reviews, free from nonsense.

Our daily newsletter delivers the most important stories straight to you every weekday.

Regardless of whether a Mustang has a price tag of $34,610 or $325,000, every vehicle begins assembly on the same production line at Ford’s Flat Rock Assembly Plant in Flat Rock, Michigan.

The Ford Mustang GTD is carefully hand-assembled by the Multimatic team, but its journey starts differently. The supercharged, track-ready Mustang utilizes the same frame as the standard Mustang, along with nearly all structural points of the body.

During the unveiling of the 2025 Ford Mustang GTD, Chief Program Engineer Greg Goodall explained to The Drive how the GTD is constructed. Here’s what we discovered.

Like every other Mustang, the GTD is assembled at Flat Rock until it reaches the stage of a body-in-white. This means that the frame and most of the surrounding body with hard points are put together like any other version of the muscle car. However, components such as the fenders, hood, and trunk are not included. The roof panel, typically welded or bonded in place, is also absent. These elements will later be added by Multimatic, specifically tailored for the GTD and manufactured from carbon fiber.

Although termed a "body-in-white," each body actually leaves Flat Rock painted black. This uniform finish guarantees that areas like the engine bay match across all vehicles.

The body-in-white, without the missing components like the roof, is then moved to Multimatic’s facility in Markham, Ontario, Canada.

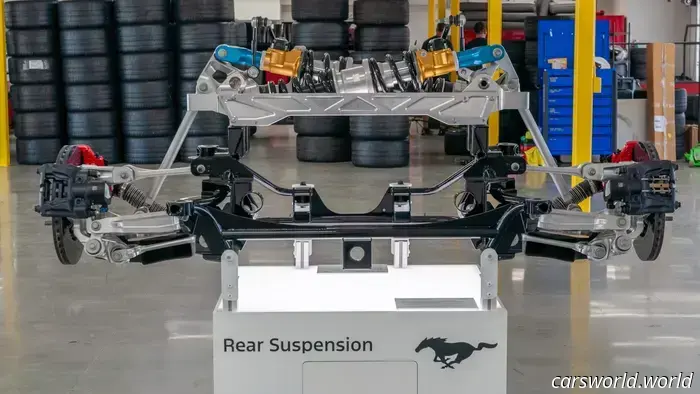

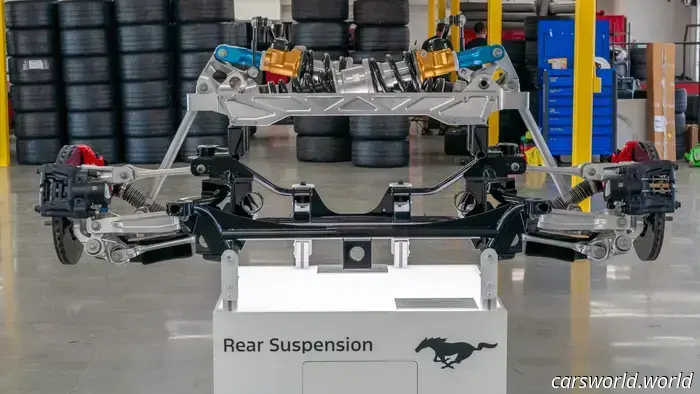

At Multimatic, the team uses a plasma cutter to remove the body side at the C-pillar (to allow for the addition of a carbon fiber piece later) and cuts out the second-row seating area to accommodate the suspension structure. They then add carbon fiber reinforcement to the base of the C-pillar area to support the rear DRS wing, ensuring that it can withstand the aerodynamic forces applied to the vehicle. Additional structural reinforcements are added below this area in the cabin to effectively transfer loads. This extra reinforcement is hidden beneath the black panel surrounding the lexan window in the rear bulkhead.

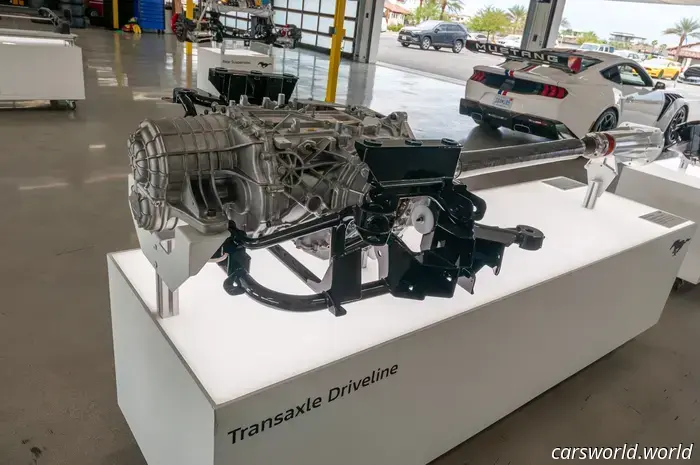

The rear floor, normally the trunk floor of the Mustang, is also cut out using the plasma cutter. Multimatic replaces it with a flat aluminum floor designed to manage noise, vibration, and harshness (NVH) from the transaxle and subframe, both of which are directly bolted to the underside of the rear floor.

Design Manager Anthony Colard mentioned that each sub-assembly, such as the gearbox, is tested on a separate dynamometer before being installed in the car.

Next, Multimatic fabricates all the carbon fiber panels, including the roof, front fenders, hood, body-side outer panels, diffusers, rocker panels, and bumpers.

The GTD then undergoes a painting process. Once painted, the car is carefully moved through 10 different assembly stages.

Ford assembles the dashboard for the GTD at Flat Rock but does not install them there. Instead, dashboards are sent to Multimatic, where the team installs them with unique trim pieces and GTD-specific software.

The 5.2-liter supercharged V8 engine begins its journey at Ford’s Dearborn Engine Plant like all Predator engines but is then shipped to Performance Assembly Solutions in Livonia, Michigan, for the addition of a dry sump system along with other GTD-specific enhancements. It is subsequently sent to Multimatic for installation.

Goodall noted that various parts from former GT 500 models and current Mustang productions, such as electrical architectures and modules, are packaged and sent to Multimatic for installation.

Custom components sourced by Multimatic, including DSSV Spool Valve Dampers and Brembo-sourced carbon-ceramic brake rotors, are integrated by the Multimatic team.

Once all components are installed, Mustang GTDs go through a "rigorous test schedule," according to Goodall. This ensures all software is operational, verifies that all features function correctly, checks for water-resistance, and puts the car on a dynamometer to ensure it generates the expected power.

Finally, the Mustang GTDs are delivered to their new owners by a specialist, providing a white-glove experience to ensure customers are fully educated on the vehicle’s features and systems.

If you have a story about how something is made, send us an email at [email protected]

Other articles

A $1,000 hands-free driving device enabled an aging Prius to travel coast-to-coast with 99% autonomy.

An aftermarket driver-assist system enabled Jay and Gypsy Roberts to finish the Cannonball Run in their 2017 Prius with minimal wheel control.

A $1,000 hands-free driving device enabled an aging Prius to travel coast-to-coast with 99% autonomy.

An aftermarket driver-assist system enabled Jay and Gypsy Roberts to finish the Cannonball Run in their 2017 Prius with minimal wheel control.

Weeds Consume Abandoned Porsche in a Scene Reminiscent of The Last of Us | Carscoops

In the Netherlands, nature has taken over a neglected Porsche 911, as locals report it has remained undisturbed for over a year.

Weeds Consume Abandoned Porsche in a Scene Reminiscent of The Last of Us | Carscoops

In the Netherlands, nature has taken over a neglected Porsche 911, as locals report it has remained undisturbed for over a year.

Kia's Most Opulent Vehicle to Date is Neither an SUV Nor a Sedan | Carscoops

The revamped Carnival Hi Limousine makes its comeback for 2026 featuring updated design, enhanced comfort, and two powertrain choices.

Kia's Most Opulent Vehicle to Date is Neither an SUV Nor a Sedan | Carscoops

The revamped Carnival Hi Limousine makes its comeback for 2026 featuring updated design, enhanced comfort, and two powertrain choices.

Toyota Executive Believes Hydrogen Will Replace Diesel

That's, um... you know, it's quite a daring forecast.

Toyota Executive Believes Hydrogen Will Replace Diesel

That's, um... you know, it's quite a daring forecast.

Korea Probes Human Rights Abuses in ICE Operation as Trump Advocates for Increased Investments | Carscoops

Seoul has stated that they will look into whether there were any "violations of human rights or discomforts experienced by our citizens."

Korea Probes Human Rights Abuses in ICE Operation as Trump Advocates for Increased Investments | Carscoops

Seoul has stated that they will look into whether there were any "violations of human rights or discomforts experienced by our citizens."

The VW Touareg is Making a Comeback, But It Will Look Different | Carscoops

The ID. Touareg expected in 2029 may be the first model to utilize VW’s new SSP electric platform.

The VW Touareg is Making a Comeback, But It Will Look Different | Carscoops

The ID. Touareg expected in 2029 may be the first model to utilize VW’s new SSP electric platform.

The Journey of a $325,000 Mustang: From the Flat Rock Assembly Line to a Custom-Built Supercar

The $325,000 Ford Mustang GTD begins its journey like any other Mustang before being handed over to Multimatic for modifications.