GM's Innovative Battery Formula Might Be Crucial for Reducing EV Costs | Carscoops

Production is set to commence in 2027, and these new batteries are expected to power the upcoming generation of budget-friendly electric vehicles.

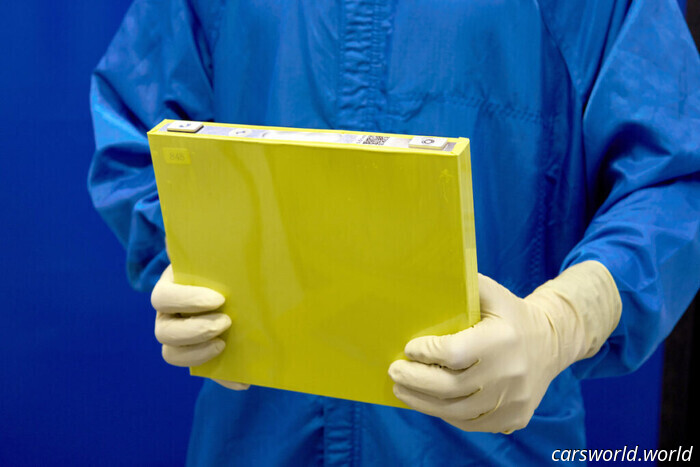

General Motors is adopting more economical lithium iron phosphate battery packs, which will be manufactured in Tennessee, with production planned for late 2027. These new batteries are anticipated to offer "significant" cost reductions in comparison to other battery chemistries.

Recently, GM revealed that the Fairfax Assembly would start producing the revamped Chevrolet Bolt by year’s end. This was anticipated, but the company also hinted at future investments aimed at their "next-generation of affordable EVs."

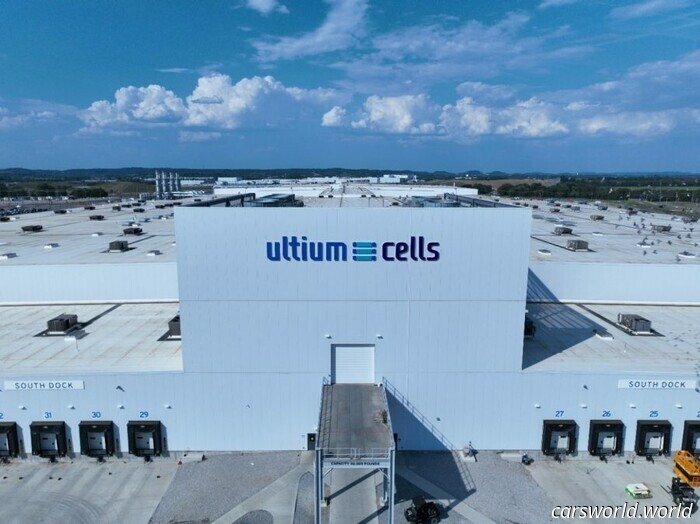

GM is reinforcing its commitment to affordable electric vehicles, as their Ultium Cells facility in Spring Hill, Tennessee will undergo upgrades to manufacture "low-cost" lithium iron phosphate batteries. Upgrades will commence later this year, with production set to begin in late 2027.

The automaker hasn’t disclosed extensive details but is "targeting substantial battery pack cost reductions" by utilizing lithium iron phosphate technology. They also indicated that this strategy will expand consumer options, as they will continue to produce batteries featuring nickel cobalt manganese aluminum chemistry.

GM’s vice president of batteries, propulsion, and sustainability stated, “This upgrade at Spring Hill will allow us to scale production of lower-cost LFP cell technologies in the U.S., complementing our high-nickel and future lithium manganese rich solutions, while further diversifying our expanding EV portfolio.”

There is currently no information about which models will use the lithium iron phosphate batteries, although the nearby Spring Hill Manufacturing facility produces the Cadillac Lyriq and Vistiq. Nevertheless, it is likely that these batteries will be used for more affordable EVs rather than luxury vehicles.

GM Remains Committed To LMR Batteries

Although GM is enthusiastic about LFP batteries, President Mark Reuss emphasized their recently introduced lithium manganese rich (LMR) chemistry. He pointed out that construction at the Ancker-Johnson Battery Cell Development Center in Michigan reached a milestone last month with the installation of the final steel beam.

When the facility opens, its primary mission will be to “advance LMR batteries into production ahead of competitors.” Reuss mentioned that this center will “significantly reduce development times for new batteries by up to a year.”

GM's Innovative Battery Formula Might Be Crucial for Reducing EV Costs | Carscoops

Production is set to begin in 2027, and they are expected to drive the next wave of cost-effective electric vehicles.