Turbocharged Chevy Inline-Six Outperforms V8s with 1,320 HP on the Dyno

Staff Bros Garage

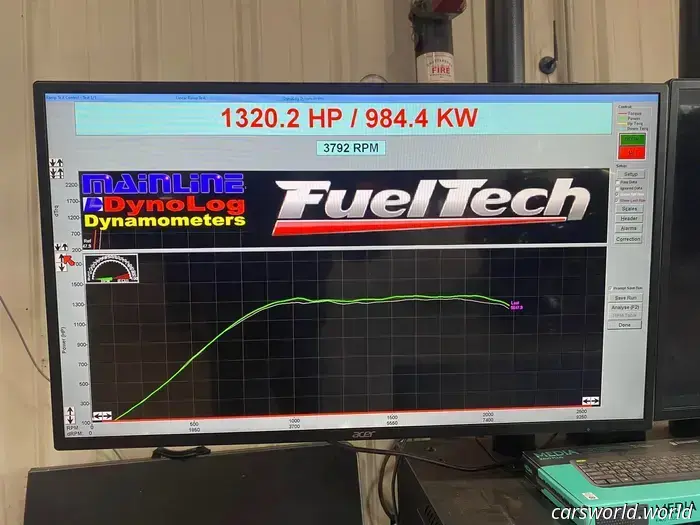

There’s something uniquely appealing about an American inline-six. Perhaps it’s the countless times I’ve heard “small-block Chevy,” outnumbering even my own name, but the straightforwardly powerful V8s hardly capture my interest anymore. Additionally, people have been enhancing six-cylinder engines for generations; some even prefer them. This 1936 Chevrolet pickup illustrates that massive power doesn’t require a V8 or large displacement, and simply based on style, it’s a build deserving of admiration. The fact that its turbocharged Chevy I6 generates over 1,300 horsepower on a hub dyno is an extra perk.

This impressive creation comes from Staff Bros Garage, which began with a 292-cubic-inch General Motors engine and then reduced it to 285 cubic inches. This choice raises some eyebrows since most engine builders opt for increased displacement; however, this approach isn’t novel. Many high-performance Barra I6 builds from Australia adopt this strategy to decrease piston travel, enabling higher revs and potentially faster speeds.

This aspect is crucial for this build as it is fitted with a Garrett 5020 Gen2 88-millimeter turbo. While there are larger turbos available, optimizing this setup requires the capability to rev to around 7,000 rpm. Achieving the 1,320 hp mark necessitated 42 psi of boost, and fortunately, the stock block remained intact. Interestingly, it was originally marked “Property of UPS,” indicating it has likely endured a tough life.

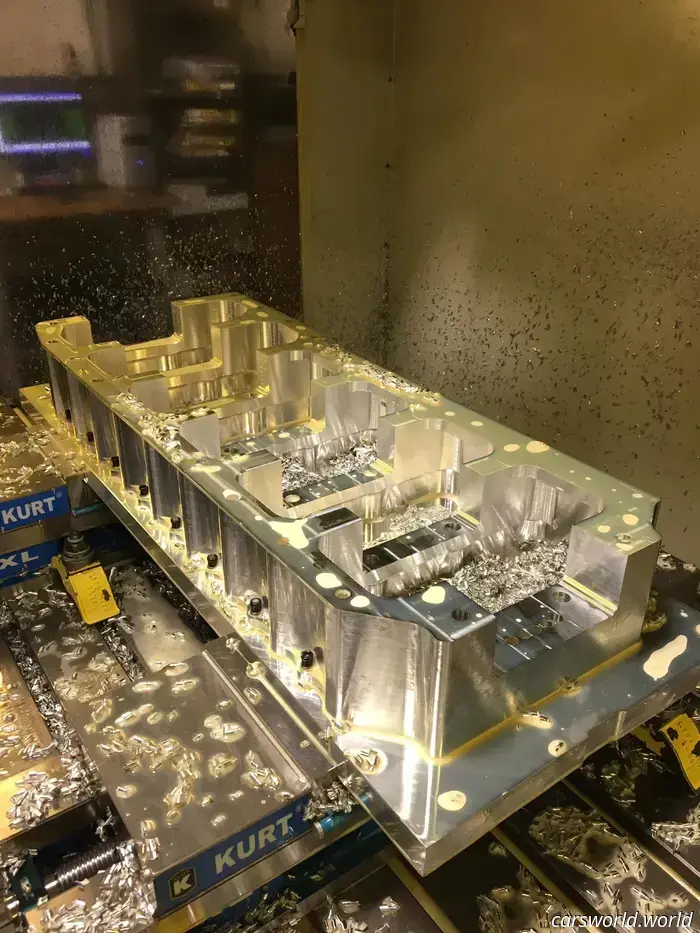

However, the stock block doesn't mean the rest of the bottom-end is unchanged. To begin with, Staff Bros Garage had a custom billet steel crankshaft made by Marine Crankshaft for this engine. The connecting rods are forged GRP units, and JE manufactured the flat-top pistons. They crafted the engine girdle in-house using 6061 aluminum, and true to a proper race build, it incorporates a dry-sump oiling system.

The Chevy engine also features a Sissell ported head equipped with a Bullet custom camshaft. Although some off-the-shelf components are available for the 292 platform, many need to be specially made. Staff Bros Garage reports spending between 300-400 hours building the I6 over the past four years, along with an estimated 1,000 hours of research. This undertaking was never going to be straightforward.

Managing the engine's operation for optimal power and efficiency is a FuelTech FT600 ECU. It also utilizes the brand’s FTSPARK ignition system, which is an essential upgrade for producing these kinds of numbers.

Staff Bros Garage

Watch and, importantly, listen to this machine on the dyno. If you're accustomed to rumbling V8s, it produces an entirely different sound, but it's still delightful music for anyone who appreciates horsepower, regardless of its source.

Other articles

Court Determines Tesla’s Autopilot is Defective for Regular Use Following Phantom Braking Incident | Carscoops

The plaintiff in Germany is requesting either compensation or a replacement Tesla that does not have any safety issues.

Court Determines Tesla’s Autopilot is Defective for Regular Use Following Phantom Braking Incident | Carscoops

The plaintiff in Germany is requesting either compensation or a replacement Tesla that does not have any safety issues.

Nikola Declares Bankruptcy as Startup Previously Valued More Than Ford Exhausts Its Funds | Carscoops

The stock of the electric truck company dropped 95 percent in the year leading up to January, and no one intervened to rescue it.

Nikola Declares Bankruptcy as Startup Previously Valued More Than Ford Exhausts Its Funds | Carscoops

The stock of the electric truck company dropped 95 percent in the year leading up to January, and no one intervened to rescue it.

Porsche 911 Faces Two New Recall Announcements | Carscoops

One recall pertains to headlights that cause glare, while the other concerns seat belt bolts.

Porsche 911 Faces Two New Recall Announcements | Carscoops

One recall pertains to headlights that cause glare, while the other concerns seat belt bolts.

Mitsubishi Revives Grandis Nameplate For Rebranded Renault Symbioz | Carscoops

The Grandis has made a comeback, re-emerging as a hybrid compact SUV aimed at young families.

Mitsubishi Revives Grandis Nameplate For Rebranded Renault Symbioz | Carscoops

The Grandis has made a comeback, re-emerging as a hybrid compact SUV aimed at young families.

Ford Eliminates Stock Bonuses for Certain Managers to Encourage Performance | Carscoops

About 50% of middle management are not receiving the stock bonuses they typically expect.

Ford Eliminates Stock Bonuses for Certain Managers to Encourage Performance | Carscoops

About 50% of middle management are not receiving the stock bonuses they typically expect.

Trump intends to impose 25% tariffs on automobiles and chips starting April 2 | Carscoops

Information regarding the newly announced tariffs has not yet been disclosed, but they now encompass semiconductor chips and pharmaceuticals.

Trump intends to impose 25% tariffs on automobiles and chips starting April 2 | Carscoops

Information regarding the newly announced tariffs has not yet been disclosed, but they now encompass semiconductor chips and pharmaceuticals.

Turbocharged Chevy Inline-Six Outperforms V8s with 1,320 HP on the Dyno

What should you do with an old Chevy 292-cubic-inch I6 engine from a UPS truck? Customize every part to make it roar down the drag strip.