Constructing this flatbed Oldsmobile Bravada work truck required 500 hours. The effort is evident.

Oldsmobile Bravada work truck with a flatbed by First Choice Fabrication

Get The Drive’s daily newsletter

Stay updated with the latest automotive news, reviews, and features.

The second-generation Oldsmobile Bravada was based on the Chevy S10 platform, but it was never intended to be a pickup truck. Instead, it was a badge-engineered Blazer that featured a slightly upgraded interior. However, you wouldn't suspect that from the work truck created by First Choice Fabrication in Colorado. Every aspect of it is so meticulously designed that it could easily be mistaken for a factory model, from the modified single cab to the exquisite flat bed and sturdy steel front bumper.

This level of craftsmanship results from approximately 500 hours invested in the project. Loren Byers, the owner of First Choice Fabrication, mentions that this was a “personal shop project” completed without a budget, and the skirted flatbed alone starts at $10,000. Estimating the cost of the rest of the modifications is challenging due to the numerous thoughtful details involved. My personal favorite is the prominently displayed Oldsmobile emblem on the headache rack, along with the branded mud flaps. I even appreciate the design of the teeth on the front brush guard.

Given the extensive modifications needed to transform the SUV into a pickup, you might wonder why he chose not to begin with a standard S10 pickup. “I wasn’t even considering building it when I bought it,” Byers explained to me over the phone. “Basically, I got it to serve as a paperweight to stand in front of my garage door at night for security. I drove it home at 80 mph; it had 105,000 miles on it and was completely clean except for a damaged rear end.”

It seems the gap between the rear door and the roof was large enough to allow a hand to fit inside.

“Water would just pour in, so it started with the idea of sealing it up to prevent water from entering the cab while still using it as a door blocker. Then it evolved into a single cab, and I thought, ‘I might as well add a bed for it and actually use it.’ From there, it just got out of hand,” Byers added.

I admire how nearly every enhancement has improved the Bravada’s functionality as a workhorse. The flat bed is certainly impressive, but the storage boxes on the sides and the numerous tie-downs on the deck itself are equally noteworthy. Auxiliary LED lights make late-night repairs in the field much easier, and the tow hooks would undoubtedly be useful for retrieving stuck equipment.

The truck is currently equipped with a stock 4.3-liter V6, but it’s nearing the end of its lifespan. “Unfortunately, just 800 miles after I completed the project—fully finished—the engine decided to fail,” Byers stated. “It was knocking and ticking and no longer running.” His planned solution is straightforward: he intends to replace it with a 5.3-liter V8 next month, which should really maximize the performance of those new BFGoodrich all-terrain tires.

While this compact and agile truck can serve a variety of purposes, Byers notes its primary function is to travel to the steel yard and powder-coat shop. He has a drop-in metal rack extending from the front bumper to the back of the bed, allowing him to transport long materials without needing a trailer. As I mentioned earlier, every aspect here was purposefully executed.

If only all trucks were constructed like this.

Have a tip or question for the author? Reach out directly: [email protected]

Другие статьи

Meet Your Icons: A Guide to Exploring Japan’s Automotive Culture with an Exciting JDM Collection

Renting a car while on vacation typically isn't the highlight—unless you receive the keys to a collection of JDM legends from Drivers Lounge.

Meet Your Icons: A Guide to Exploring Japan’s Automotive Culture with an Exciting JDM Collection

Renting a car while on vacation typically isn't the highlight—unless you receive the keys to a collection of JDM legends from Drivers Lounge.

VW's Upcoming Electric Vehicles May Utilize a Platform They Did Not Construct | Carscoops

Rivian states that Volkswagen will maintain distinct styling, interfaces, and suspension adjustments for every specific model.

VW's Upcoming Electric Vehicles May Utilize a Platform They Did Not Construct | Carscoops

Rivian states that Volkswagen will maintain distinct styling, interfaces, and suspension adjustments for every specific model.

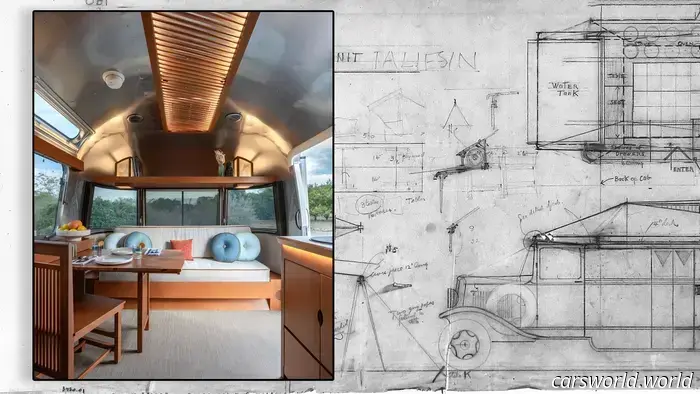

Frank Lloyd Wright’s Overlooked Food Truck Concept Inspired a New Airstream Trailer.

The $185,000 Airstream Frank Lloyd Wright Usonian Limited Edition Travel Trailer incorporates several of the renowned designer's principles into a camper.

Frank Lloyd Wright’s Overlooked Food Truck Concept Inspired a New Airstream Trailer.

The $185,000 Airstream Frank Lloyd Wright Usonian Limited Edition Travel Trailer incorporates several of the renowned designer's principles into a camper.

Nissan's Upcoming Nismo SUV Has Just Arrived Dressed Only in Red Accents | Carscoops

The most athletic variant of the Armada, as we recognize it, was seen without any camouflage while reaching dealerships in the Middle East.

Nissan's Upcoming Nismo SUV Has Just Arrived Dressed Only in Red Accents | Carscoops

The most athletic variant of the Armada, as we recognize it, was seen without any camouflage while reaching dealerships in the Middle East.

Receive complimentary Milwaukee tools with the purchase of batteries during The Home Depot's Father's Day Sale.

Purchase a Milwaukee M18 lithium-ion starter kit that includes two batteries and a charger (currently discounted), and choose one out of 12 Milwaukee power tools to receive at no cost.

Receive complimentary Milwaukee tools with the purchase of batteries during The Home Depot's Father's Day Sale.

Purchase a Milwaukee M18 lithium-ion starter kit that includes two batteries and a charger (currently discounted), and choose one out of 12 Milwaukee power tools to receive at no cost.

The $6.5 Million Aston Martin Valkyrie LM Comes with a Higher Price Tag for Lower Power Output.

The latest Aston Martin Valkyrie LM boasts 300 less horsepower compared to the AMR Pro and is priced at an additional $2 million, as it is a genuine race car.

The $6.5 Million Aston Martin Valkyrie LM Comes with a Higher Price Tag for Lower Power Output.

The latest Aston Martin Valkyrie LM boasts 300 less horsepower compared to the AMR Pro and is priced at an additional $2 million, as it is a genuine race car.

Constructing this flatbed Oldsmobile Bravada work truck required 500 hours. The effort is evident.

The attention to detail in this labor of love is remarkable. I doubt that General Motors itself could produce something this pristine straight from the factory.