Inside Hyundai's 650-Foot Cargo Ship Anchored at the Largest Car Manufacturing Plant in the World

Getty

Sign up for The Drive Daily

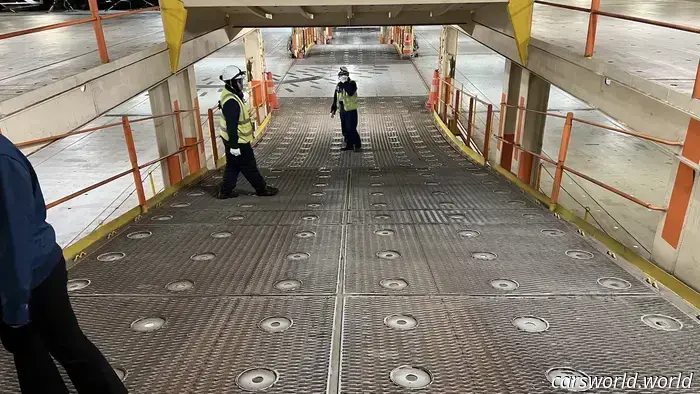

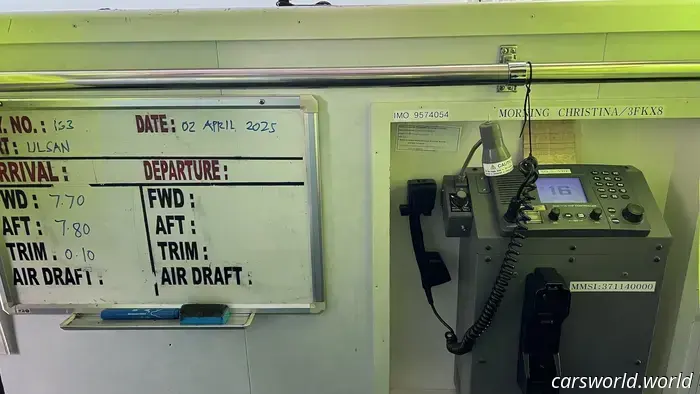

Looking up from the dock, the Morning Christina resembles a skyscraper more than a typical ship. Despite its whimsical name, the 656-foot-long vehicle carrier is an enormous metal entity that traverses the world's oceans like we commute to work. On this particular day, it's docked in Ulsan, South Korea, the site of Hyundai Motor Group's extensive industrial complex and the largest automobile factory in the world. I've been granted rare access to the ship and wear a high-visibility vest.

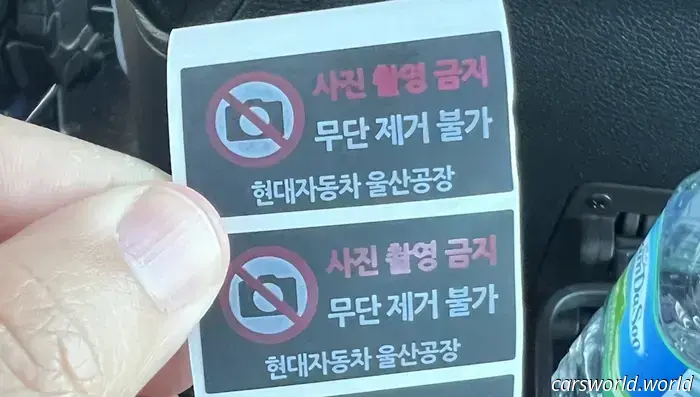

As I ascend the ramp to enter the ship, I’m informed that photography of both the vessel and its cargo is prohibited. While it’s an unusual request for a journalist, it’s understandable under certain conditions. I politely requested some flexibility regarding the photo rule, and after a brief discussion between the automaker’s PR and ship staff, I received approval to take pictures—albeit with the restriction of no photos of the cars.

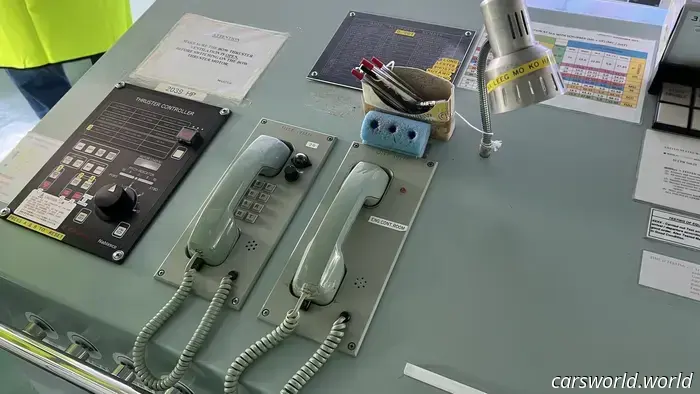

This is my first experience inside a cargo ship, and even though I have been on large cruise ships before (both as a passenger and crew), I’m struck by the sheer size, layout, and overall atmosphere inside. The ship's interior is cold and metallic, with an odor combining tire rubber, industrial grease, exhaust fumes, and a hint of sea salt. It’s clearly not designed for comfort but solely for the efficient and safe transportation of cars.

The atmosphere among the port workers and some of the ship’s crew is quite frantic as they rush about, conversing in Korean, Filipino, English, or a mix of the three. They are under pressure to adhere to a tight schedule, and having a group of journalists in the way is understandably frustrating. If everything goes smoothly, the Morning Christina should be loaded with thousands of cars by day’s end and set sail for the Port of Los Angeles shortly thereafter.

Car Exports

The practice of using cargo ships for vehicle exports is neither new nor particularly complicated. The process involves rolling a number of cars onto a ship and sending it off. Once it arrives at its destination, the cars are driven off. While this seems straightforward, transporting nearly 7,000 cars across open water for about two weeks entails a lot of logistics. If we've learned anything from incidents involving the Ever Given in 2021 and the Felicity Ace in 2022, it's that many things can go awry.

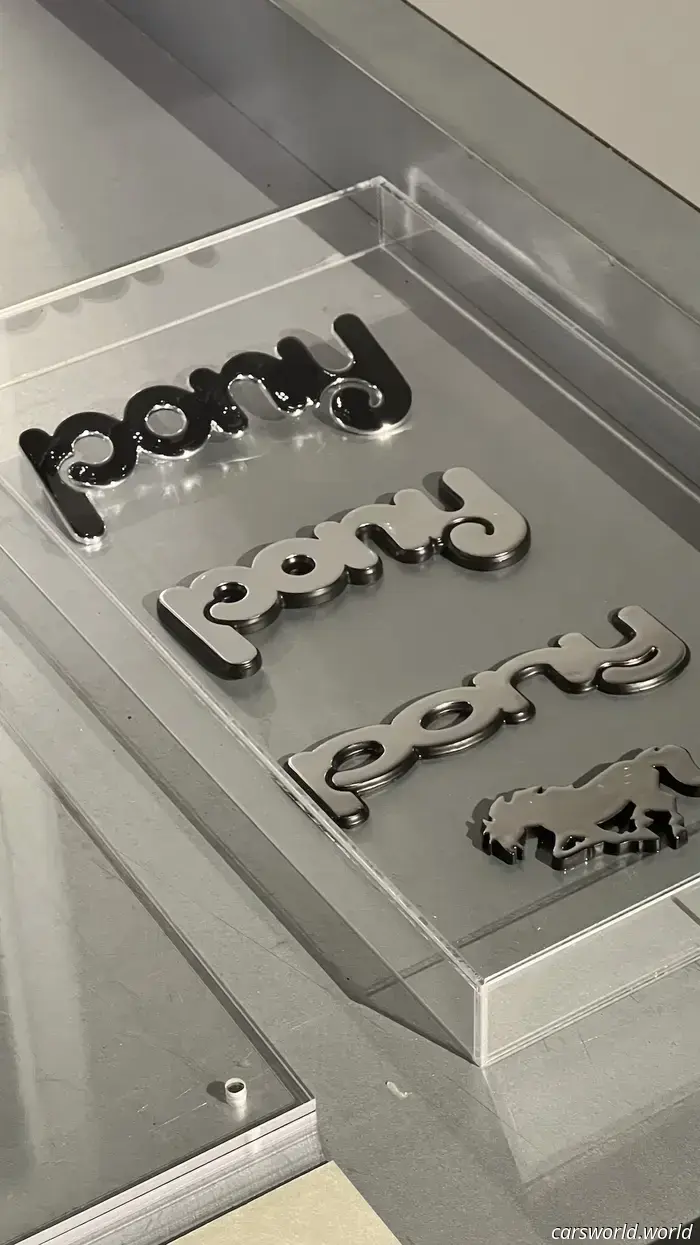

The Ulsan industrial complex where the Morning Christina was docked began operations in 1968 with the production of the *drumroll please* Ford Cortina. Yes, the first car manufactured by Hyundai was, in fact, a Ford. By 1975, Hyundai decided to create its own distinct model, resulting in the Pony. A year later, Hyundai entered the export market, sending the Pony to around a dozen countries.

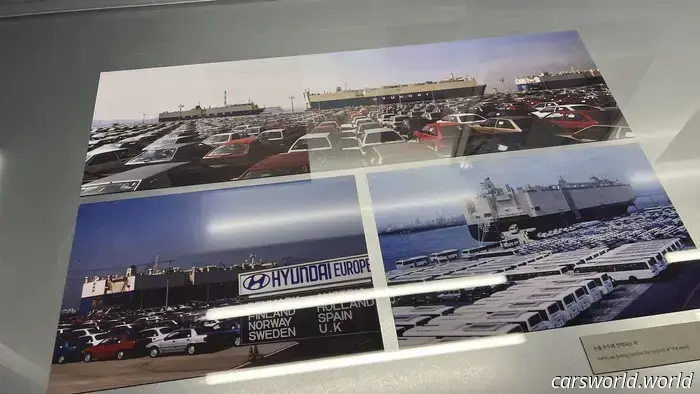

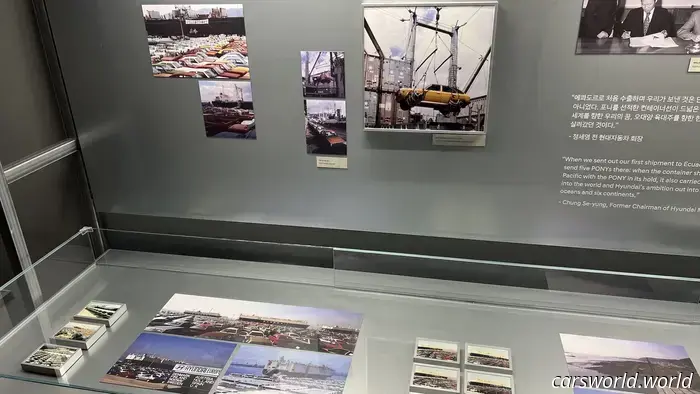

The logistics for vehicle exports at that time were significantly different from today, as illustrated in photographs from Hyundai’s Ulsan museum. Workers used to secure nylon nets around the Pony's tires and lift them with a crane, which would lower each car onto the cargo ship’s top deck. Cars were parked like they were in a Walmart parking lot. In the early days, a variety of methods were tried, including placing cars in containers.

Korea began its foray into the RoRo (roll on, roll off) shipping business in the late 1970s, with the shipping company Eukor and Hyundai launching their first model in 1980, which greatly streamlined the export process. From then on, the vast parking areas full of cars would be driven onto the various decks of a ship, saving the manufacturer considerable time and resources. As I observed that day, the drivers who loaded the cars took their job seriously and drove with speed.

Inside the Ship

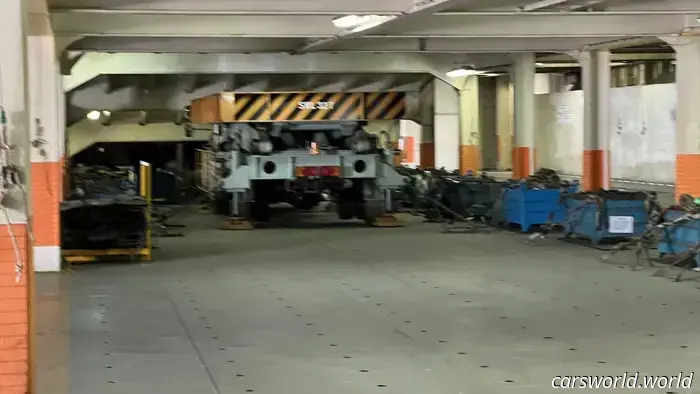

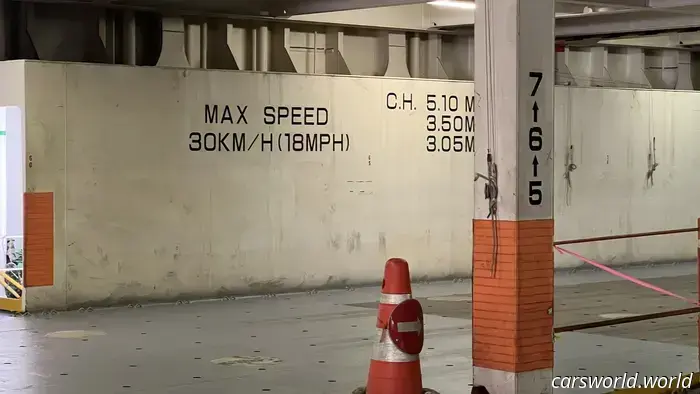

If you were blindfolded and then brought into the Morning Christina before removing the blindfold, you might think you were in a multi-level parking garage at first glance. There's almost nothing about it that indicates you're on water. The only hint might be the metal floors instead of concrete, but the ramps, columns, and doors all resemble a parking facility.

However, if you look closely, you’ll see small details that reveal a bigger story. For instance, there’s grip tape everywhere to address the risks of damp and slippery metal surfaces, necessitating creative solutions for safe movement.

There are numerous signs throughout the ship, explaining how to properly park and secure vehicles. Some caution drivers about different car shift patterns and the positioning of reverse gears, while others address maritime and fire safety, along with rules and expectations while at sea.

The most striking element inside the ship is the countless small voids. No matter where you stand, there’s a hole, another hole, and more holes around. These are all anchoring points.

Not for the ship’s anchor, but for the straps that secure the cars. Each vehicle that is loaded is fastened to the floor with straps

Other articles

The iconic Bose Magic Carpet Suspension is set to make its global debut.

Bose once amazed us with a vehicle that was capable of leaping over potholes and providing a perfectly smooth ride. Now, after more than 20 years, the technology is finally entering mass production.

The iconic Bose Magic Carpet Suspension is set to make its global debut.

Bose once amazed us with a vehicle that was capable of leaping over potholes and providing a perfectly smooth ride. Now, after more than 20 years, the technology is finally entering mass production.

Teen Expected to Face 'Decades in Prison' After Allegedly Firebombing Cybertrucks | Carscoops

The FBI, along with local authorities in Kansas City, is looking into the incident.

Teen Expected to Face 'Decades in Prison' After Allegedly Firebombing Cybertrucks | Carscoops

The FBI, along with local authorities in Kansas City, is looking into the incident.

The Italian Job: $218K Ferrari Roma Vanished While Heading to Dealership

A federal lawsuit filed by the dealer alleges that a bogus shipping company intercepted the Ferrari, which has yet to be found.

The Italian Job: $218K Ferrari Roma Vanished While Heading to Dealership

A federal lawsuit filed by the dealer alleges that a bogus shipping company intercepted the Ferrari, which has yet to be found.

Would you entrust your life to the Jack Rod?

For many years, DIY enthusiasts and trackside mechanics have been utilizing jack locks. When used in the appropriate context, they can be quite beneficial.

Would you entrust your life to the Jack Rod?

For many years, DIY enthusiasts and trackside mechanics have been utilizing jack locks. When used in the appropriate context, they can be quite beneficial.

New Land Rover Defender 'Sport' EV: What We Know | Carscoops

The second model in the Defender lineup will compete with the soon-to-be-released compact G-Class from Mercedes-Benz.

New Land Rover Defender 'Sport' EV: What We Know | Carscoops

The second model in the Defender lineup will compete with the soon-to-be-released compact G-Class from Mercedes-Benz.

Buick's return is facing significant challenges due to tariffs.

Buick experienced a 39% rise in sales in the first quarter of 2025, yet its top three best-selling models are sourced from Asia and are directly affected by tariffs.

Buick's return is facing significant challenges due to tariffs.

Buick experienced a 39% rise in sales in the first quarter of 2025, yet its top three best-selling models are sourced from Asia and are directly affected by tariffs.

Inside Hyundai's 650-Foot Cargo Ship Anchored at the Largest Car Manufacturing Plant in the World

Moving 6,900 vehicles across an ocean is quite an accomplishment.