Reviving This Vintage Sleeve-Valve Engine After 60 Years Was a Passionate Endeavor

I'm uncertain if any engines manufactured today will still be salvageable in a century. I don't mean to sound pessimistic, but so much relies on technology that will likely be outdated by then. Furthermore, the quality of materials used in modern manufacturing is concerning. While this thought is somewhat disheartening, it makes me appreciate the revival of this old Willys-Knight sleeve valve engine even more, especially since someone in 2025 managed to get it running after sitting unused for over 60 years.

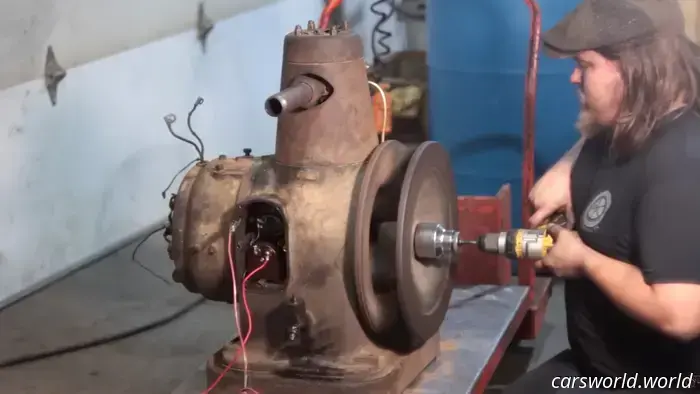

Here it stands in all its unrestored splendor. cruddycornstalks via YouTube

If you're not familiar with these engines, let me give you a brief overview. Charles Yale Knight developed the sleeve valve engine in the early 1900s, and it gained some popularity in luxury cars like those made by Willys over the following two decades, long before jeeps were introduced.

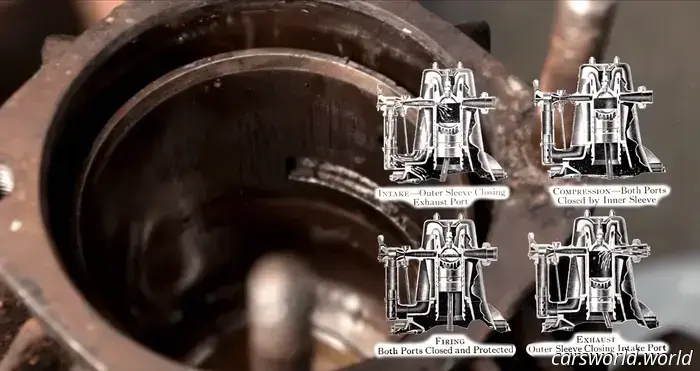

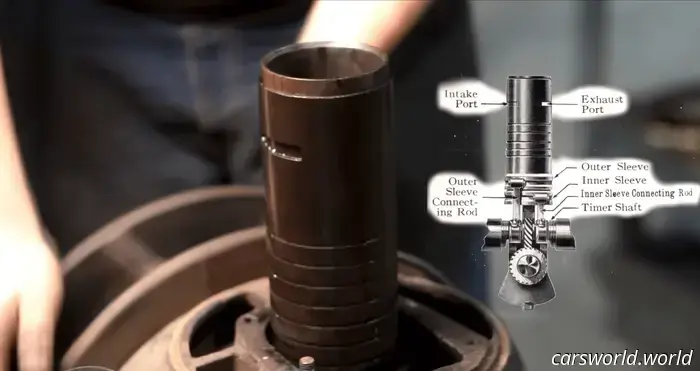

They are somewhat akin to valveless four-stroke engines in that they lack a conventional valvetrain with components like camshafts, rocker arms, and pushrods. Instead, there are two cylinder sleeves—an inner and an outer—that operate through individual connecting rods. As these sleeves move up and down, they sequentially uncover the intake and exhaust ports to allow air in and out. Moreover, there is no head gasket; the seal is formed by the sleeves sliding into the uniquely designed head. It's similar to an inverted piston with rings that fit inside the inner sleeve. It may sound complicated, but don’t worry; it somewhat is.

Thankfully, the person behind the cruddycornstalks YouTube channel is skilled in this area, allowing viewers to see the sleeve valve engine in operation toward the end of the video. However, skipping to that moment would be inconsiderate, as he invested significant effort into making this engine run after decades of inactivity. He not only disassembled and cleaned it but also rebuilt the ignition system's points, adjusted the timing, and replaced the malfunctioning oil pressure gauge with a reliable piston plunger device that rises to indicate flow and falls when there is none.

These overlaid diagrams should aid your understanding of its operation. cruddycornstalks via YouTube

The video is well-produced, with no distracting background music, making it enjoyable to watch. The host alternates between slightly accelerated mechanics work and informative commentary as he disassembles and reassembles the engine.

It's remarkable to see it running at such low RPMs on his first attempt. To demonstrate the reliability of this design, it operated for 10 minutes at an extremely low idle with the side covers removed, despite this negatively impacting the engine's vacuum. Once he realized his mistake, he reattached the side covers, tidied everything with WD-40 and a rag, and manually cranked it. Surprisingly, it started effortlessly.

Polished and looking good. cruddycornstalks via YouTube

Since there is no conventional valvetrain making noise inside, the sleeve valve engine operates very quietly. The host demonstrates this by covering the exhaust with a rag, allowing viewers to hear how little noise it makes aside from that. Additionally, in a fascinating inside view, he pointed the camera into the exhaust port to show the combustion chamber as it operates. Make sure to check that out at the very end, but be aware of the epilepsy warning due to frequent flashes.

I'm pleased to have watched this and happy to share it with you. Once again, I'm unsure if we will see anything from today featured in a similar video a century from now, but I remain hopeful.

If you have a tip or question for the author, you can reach out directly at [email protected]

Other articles

Trump's rollback of electric vehicle regulations could lead to a $1 billion expense for taxpayers.

The federal government will incur a loss of $225 million solely due to the depreciation associated with the sale of 25,000 EVs that it owns.

Trump's rollback of electric vehicle regulations could lead to a $1 billion expense for taxpayers.

The federal government will incur a loss of $225 million solely due to the depreciation associated with the sale of 25,000 EVs that it owns.

The PV5 Represents Kia's Concept for an Electric Minivan | Carscoops

The PV5 can be viewed as an ID.Buzz tailored for Uber drivers and businesses.

The PV5 Represents Kia's Concept for an Electric Minivan | Carscoops

The PV5 can be viewed as an ID.Buzz tailored for Uber drivers and businesses.

Dodge Highlights Charger's Standard All-Wheel Drive System As Discounts Exceed $12,000 | Carscoops

Following a cold response, Dodge is attempting to market the Charger through any means necessary.

Dodge Highlights Charger's Standard All-Wheel Drive System As Discounts Exceed $12,000 | Carscoops

Following a cold response, Dodge is attempting to market the Charger through any means necessary.

Forza Horizon 5 Launches on PlayStation on April 29 with Improved Graphics for PS5 Pro.

The launch will also feature the introduction of Horizon Realms, along with enhanced graphics modes that surpass what is achievable on Xbox Series X.

Forza Horizon 5 Launches on PlayStation on April 29 with Improved Graphics for PS5 Pro.

The launch will also feature the introduction of Horizon Realms, along with enhanced graphics modes that surpass what is achievable on Xbox Series X.

Score the Ultimate Garage Gadget with These Offers on Borescopes and Thermal Cameras

Make the most of significant savings on the borescopes and thermal cameras we've assessed, tested, and are currently using in our garages.

Score the Ultimate Garage Gadget with These Offers on Borescopes and Thermal Cameras

Make the most of significant savings on the borescopes and thermal cameras we've assessed, tested, and are currently using in our garages.

Woman Arrested With Explosives Following Vandalism at Tesla Dealership | Carscoops

The individual is currently confronting multiple felony charges in connection with the incident.

Woman Arrested With Explosives Following Vandalism at Tesla Dealership | Carscoops

The individual is currently confronting multiple felony charges in connection with the incident.

Reviving This Vintage Sleeve-Valve Engine After 60 Years Was a Passionate Endeavor

This "valveless" four-stroke remained idle for over sixty years, and it's wonderful to see someone restore it to working condition.